한국어로 페이지 보기

Seoul ADEX 2025 Digital Directory

Plan your trip to Seoul ADEX 2025 using our state of the art Digital Directory

Register in seconds with just your email

Directory Features

To help you at the show

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

Plan your trip

Use the bookmarking and event planning tool to research the companies you would like to visit and the products you are interested in finding. You will be able to locate all of your saved companies on our floorplan

Advanced Search

Utilize our advanced search function to quickly locate products, people, and companies. Our state-of-the-art technology thoroughly scans all exhibitor information, delivering precise and relevant results

Interactive Floorplan

Navigate the show effortlessly with our directory. Use the floorplan to locate companies you want to visit and to find your way to onsite restaurants, toilets and site entrances and exits.

On-platform Messaging

Reach out to exhibitors and visitors directly on our platform to set up meetings, or request more information.

Some of our latest content

Companies, Products, News, Events

WOOSUNGSITEK

JEFF FIREFLY Military Sunglasses

JEFF FIREFLY is a perfect sunglasses for protecting the eyes and preventing reflection during daily or guard work.

The glasses block wind and dust to protect the eyes.

The Anti-Scratch & Anti-Fog coated polycarbonate lenses give you UV protection below 400nm.

The TR-90 frame offers reliable comfort during use, as it is resistant to temperature changes even in extreme conditions such as deserts or harsh climates.

Also, JEFF FIREFLY is comfortable to wear for a long time due to its lightweight fitting.

Hydraulics International Inc.

Hydraulics International, Inc. At A Glance

Hydraulics International, Inc. (HII), headquartered in Chatsworth, California, U.S.A., is a leading worldwide supplier of integrated products, services and support to military forces, aviation and commercial industries, Government agencies and prime contractors. Focused on defense and commercial technology, the Company develops, manufactures and supports a broad range of systems for over one hundred industries as well as mission-critical and military sustainment requirements over the globe. Our extensive design capabilities enable us to produce the most sophisticated technological units known in the Aircraft Ground Support Equipment (AGSE) profession.

HII has been recognized as one of the largest defense ground support equipment technology companies in the world. We hold leading market positions in ammunition loading systems, aircraft hydraulic system testing, aircraft cabin pressure testing, power systems, environmental control systems, military trailers, high-pressure gas and liquid systems, flow measuring equipment, and integrated logistics and support services.

Our corporate, engineering and manufacturing facilities, located in Chatsworth, CA and Forsyth, GA, encompass over 625,000 sq. feet of production space. Our manufacturing facility is equipped with state-of-the-art equipment such as CNC lathes and mills, computerized tube bending, full sheet laser and waterjet, automatic press brake and programmable punch press, laser topography scanners, and other quality verification devices.

HII has been recognized as one of the largest defense ground support equipment technology companies in the world. We hold leading market positions in ammunition loading systems, aircraft hydraulic system testing, aircraft cabin pressure testing, power systems, environmental control systems, military trailers, high-pressure gas and liquid systems, flow measuring equipment, and integrated logistics and support services.

Our corporate, engineering and manufacturing facilities, located in Chatsworth, CA and Forsyth, GA, encompass over 625,000 sq. feet of production space. Our manufacturing facility is equipped with state-of-the-art equipment such as CNC lathes and mills, computerized tube bending, full sheet laser and waterjet, automatic press brake and programmable punch press, laser topography scanners, and other quality verification devices.

DN Solutions

DLX series

Highest Productivity with reliable part quality

• Maximize productivity by using up to 4 lasers, advanced scanning strategies and bidirectional recoating.

• Maintain reliable part quality by using uniform gas flow and precise 3-axis scanner motions.

• All features are designed with minimizing the cost per part in mind to maximize your profitability.

Automation of processes and minimize job to job time.

• For increased operational efficiency, powder handling, powder sieving are optimized.

• The job to job time is minimized by using exchangeable build containers.

Best in class volume

• Offering uninterrupted 24/7 series production utilizing the segment‘s largest build volume and sophisticated powder management.

• This allows for printing of a wide range of mid to large size fully functional components.

Easy to Print with a wide range of materials

• DLX enables the production of highly precise and high-quality printed parts with a wide range of materials.

• Standard materials are Aluminium, Titanium, Copper, Inconel, Maraging Steel, Stainless Steel and more.

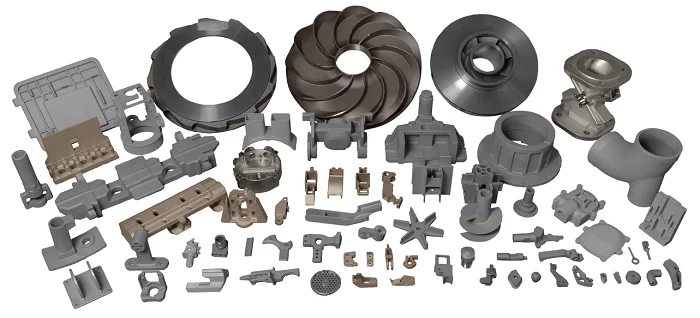

Korea Lost-wax Co., Ltd

General Industry

By supplying the highest level of products and services based on careful quality control management,

our products have been recognized by various customers.

View page in English

디렉터리 기능

전시회 도우미

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

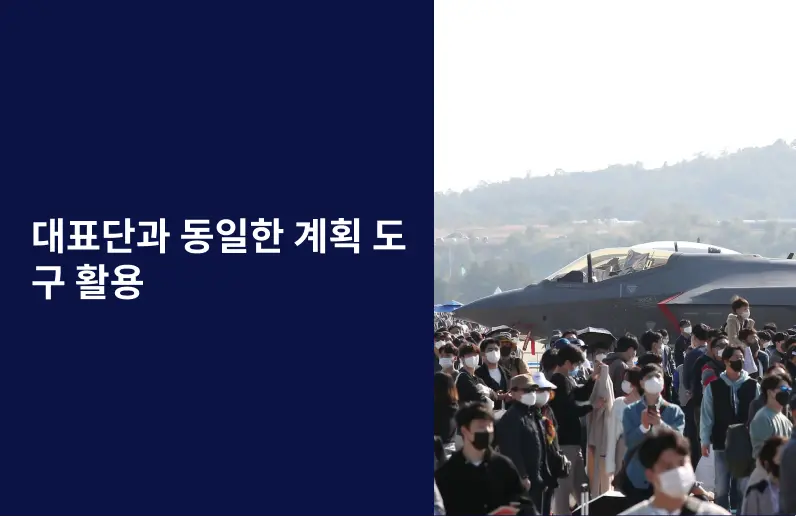

방문 계획 수립

북마크 도구와 이벤트 플래너를 사용해 방문하고자 하는 기업과 관심 있는 제품을 검색하세요. 저장한 모든 항목을 조회할 수 있습니다

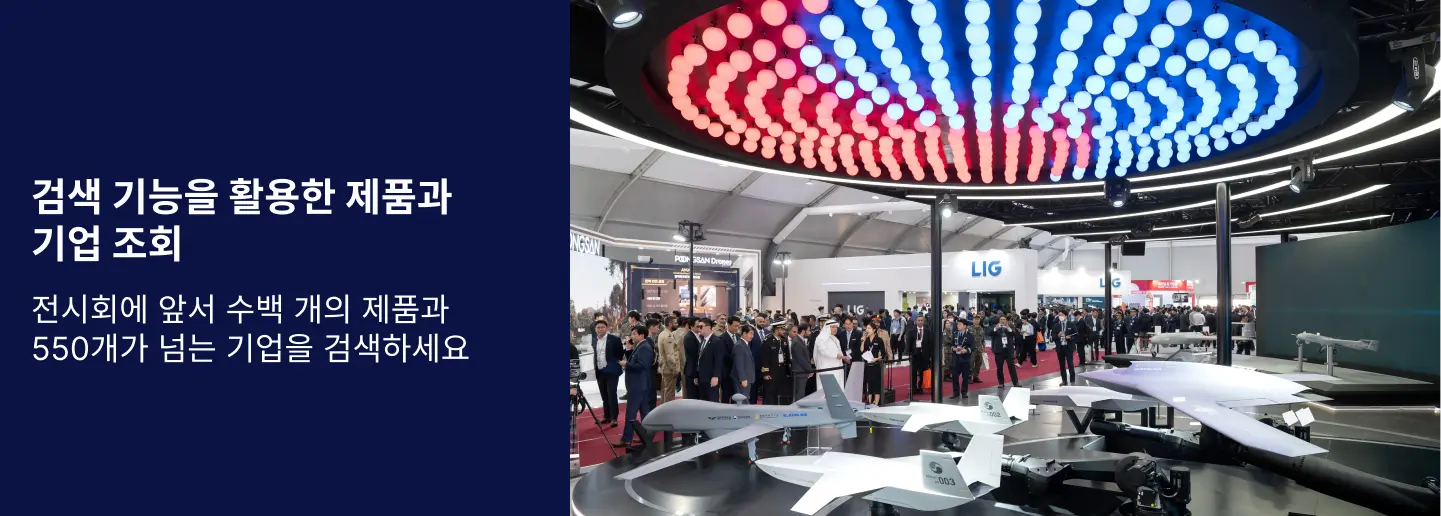

고급 검색

고급 검색 기능을 사용하여 상품, 인물, 기업의 위치를 빠르게 조회할 수 있습니다. 최첨단 기술을 통해 모든 참가사의 정보를 철저히 스캔하여 세밀하고 관련성 있는 정보를 제공합니다

상호작용 가능 평면도

디렉터리를 사용해 전시회를 손쉽게 둘러보세요. 방문하고자 하는 기업의 위치와, 행사장 내 식당, 화장실, 출입구를 평면도에서 찾을 수 있습니다.

플랫폼 내 메시지

플랫폼 상의 전시 참가사와 관람객에게 직접 연락하여 미팅을 신청하거나 추가 정보를 요청하세요.

최신 콘텐츠

기업, 상품, 뉴스, 이벤트

_700.webp)

LUMIR

Ka-band Transmitter and Phased Array Antenna, KAPA

This Ka-band antenna and data transmission device incorporates electronic beam steering antenna technology and software-defined radio technology as part of the Ka-band downlink system for satellites. It serves as a key component of data downlink systems within the satellite payload, supporting high-speed data transmission. The device enables system optimization through miniaturization, lightweight design, and single-unit modularization.

Kappa optronics GmbH

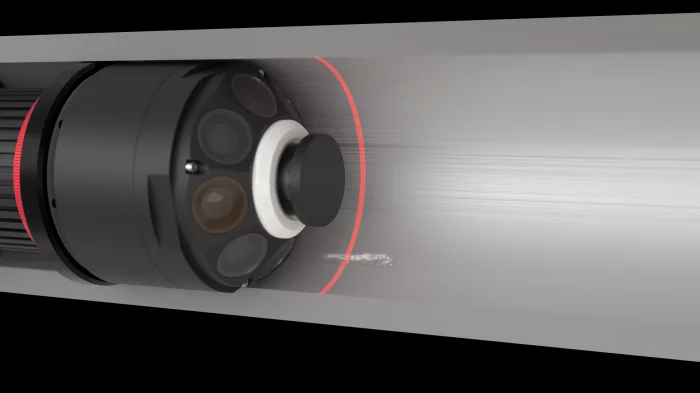

RIB 4D: Advanced Laser/Camera Inspection System for High-Caliber Gun Barrels

Combined laser scan/video scope technology for gun barrel inspection, superior measuring results:

With the RIB 4D, Kappa presents a new, high-performance system for large-caliber weapon barrel inspection designed for troops evaluating actual and post-firing status and calculating remaining service life.

3D Laser Scanner and 360° Videos: Within the completely newly designed RIB 4D measuring head, the entire bandwidth of the newest image-generating technology for seamless, complete barrel inspection is used. A supersensitive laser scan generates a detail-rich point cloud. In addition, 8 CMOS sensors provide the viewer with brilliant 360° videos of the barrel’s interior surfaces. The highly precise barrel digitization offers a comprehensive data basis for secure assessment of a barrel interior’s condition.

Keeping it simple: only one operator required

Simple handling means that just one person can operate the entire system. Independent of the operator, the automatic system delivers clear and reproducible measurement results. The barrel digitization is the reliable data basis for the subsequent location-independant assessment of the barrel condition. The compact system is designed for versatile use.

One system for multiple barrel types and diameters

RIB 4D is made for smooth and rifled barrels. With adapter rings, the system can easily be used for different calibers. The current RIB 4D version covers the range from 120 mm to 155 mm. Another version for smaller diameters is in preparation.

Ultra-fast fully-automated barrel digitization (< 30 min.)

The RIB 4D completes the entire high-resolution and precise measurement of the inside of the gun barrel sensationally fast in under 30 minutes (example Leopard 2), which speeds up and largely automates maintenance for system users and thus simplifies it to a great extent.

Interactive Software for Reliable Assessment: The extensive data of the inspected surface is analyzed in the user-friendly application software and can be documented and evaluated as a report according to the service regulation TDv018. The interactive interface supports the detection and measurement of critical damaged areas and the final evaluation of the barrel condition and the determination of the remaining service life.

Digitization of the inner barrel surface and precise measurement of damaged areas: The analysis covers erosion, corrosion, damage to the chrome coating including diameter measurement of the fields and lands and groves on rifled barrels.

Complete solution all-in-one: The non-contact RIB 4B inspection system consists of the sensor head, the drive unit, the container with the drive chain, the server, the analysis laptop and extensive accessories.

An unrivaled level of experience: We are the pioneering supplier in the area of gun barrel inspection; we know our customers’ requirements inside and out. Rely on our state-of-the-art systems based on modern technologies and decades of experience.

Versatile use: Suitable for all smooth and rifled tubes in diameters between 120 mm and 155 mm used in tanks, artillery systems and naval guns.

Reliable detection of damage

Precise scanning of the damaged areas - quick location - simple measurement

The system includes the noxRIB4D application software for system control, surface inspection and reporting. In the first step, the pipe is completely digitized on site with RIB 4D. Based on the data, the subsequent analysis can be carried out in the software independent of location. The noxRIB4D software offers two analysis screens, the Heat Map and the Intensity Map, for precise damage analysis. Finally, the analysis results are reported in Excel or TDv018 with evaluation of the barrel condition.

COTS product: Direct market availability RIB 4D for 120 mm and 155 mm. Other diameter sizes with minor adjustments without new development.

_700.webp)

MTG

Dual-Ridged Horn

Features

● Wideband Frequency Range of 2.0~18.0GHz

● Rigid Construction with AL Brazing

● Monotonic Beam Shape, No Beam Split

● Optimized Gain Ripple and VSWR

Applications

● General Purpose TX/RX Antenna

● EMC Testing

● TX/RX Antenna for EW Testing

● Wideband TX Antenna for Anechoic Chamber

.jpg)

Haynes International

Products and Capabilities

Digital Directory

Digital Directory