한국어로 페이지 보기

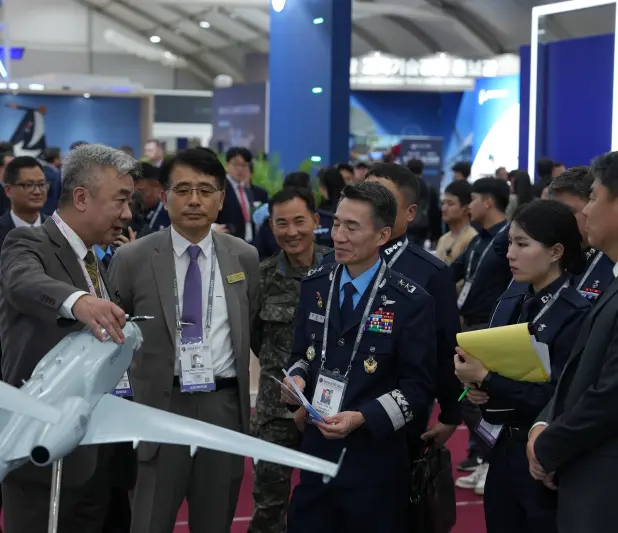

Seoul ADEX 2025 Digital Directory

Plan your trip to Seoul ADEX 2025 using our state of the art Digital Directory

Register in seconds with just your email

Directory Features

To help you at the show

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

Plan your trip

Use the bookmarking and event planning tool to research the companies you would like to visit and the products you are interested in finding. You will be able to locate all of your saved companies on our floorplan

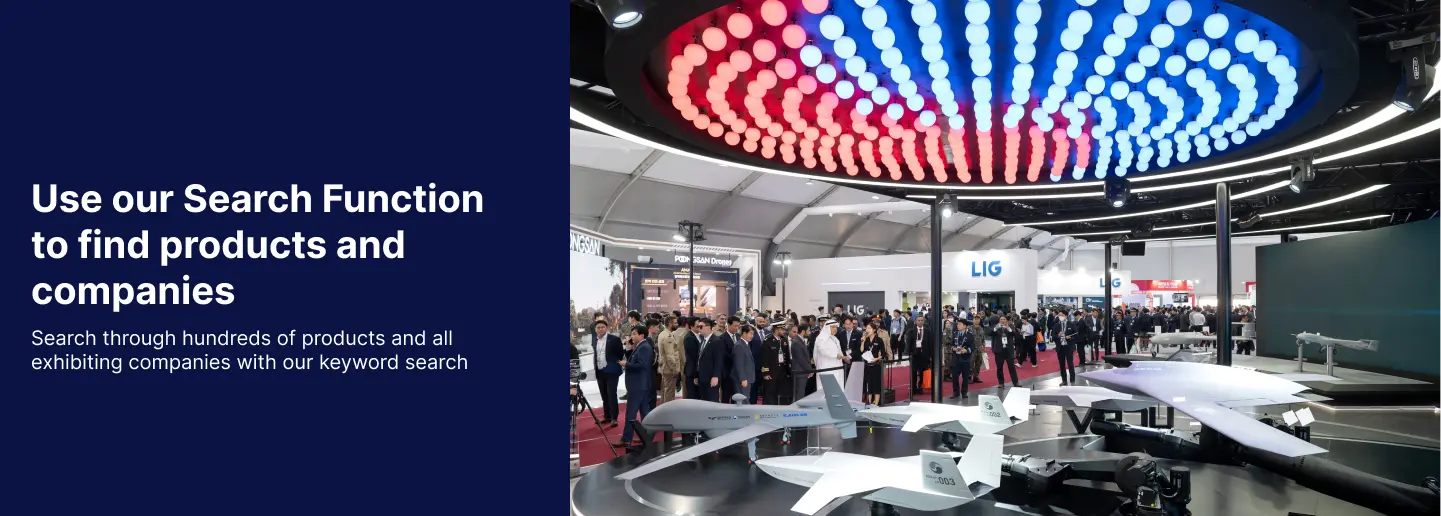

Advanced Search

Utilize our advanced search function to quickly locate products, people, and companies. Our state-of-the-art technology thoroughly scans all exhibitor information, delivering precise and relevant results

Interactive Floorplan

Navigate the show effortlessly with our directory. Use the floorplan to locate companies you want to visit and to find your way to onsite restaurants, toilets and site entrances and exits.

On-platform Messaging

Reach out to exhibitors and visitors directly on our platform to set up meetings, or request more information.

Some of our latest content

Companies, Products, News, Events

EUCAST

EL4000 - LTE outdoor (eNodeB)

The EL4000 is an RU/DU-integrated LTE outdoor base station that provides long-distance LTE service outdoors and has been supplied through KT for the Ministry of Oceans and Fisheries’ LTE-M network.

MPS bearings Co., Ltd.

Linear bearings - L series

MPS Microsystems is specialized in manufacturing high-precision, miniature linear bearings. We offer a comprehensive range of exceptionally smooth bearings with bore diameters from Ø 2 mm to Ø 6 mm.

The balls of these precision bearings meet ‘Grade 3’, the highest quality defined by the ISO 3290/DIN 5401 standard. Combined with a cage and a high precision casing, they allow rapid positioning while reducing friction and eliminating the stick-slip effect.

The standard version of MPS Microsystems linear bearings consists of a stainless steel bushing and balls, and a brass cage. An all-stainless steel version or one with ceramic balls can be made on request.

Conflux Technology

Gas-to-Liquid Heat Exchanger

Gas-to-liquid heat exchangers, also known as air-to-water or water-to-air heat exchangers, are critical in high-performance environments where efficient thermal management determines reliability and output. They are widely used in applications such as engine charge air cooling, exhaust gas heat recovery, avionics thermal control, cryogenic fluid conditioning, and high-temperature gas handling.

German Aerospace Center (DLR)

Neustrelitz Receiving Station

Neustrelitz is located 100 kilometres north of Berlin. Here, DLR receives data from the German radar missions TerraSAR-X and TanDEM-X, the KOMPSAT satellites of the Korean Aerospace Research Institute (KARI), the European Sentinel fleet and the American Landsat series, among others. The multi-antenna and multi-mission configuration of the ground station allows information products to be delivered to customers within minutes after data reception. These include products for national and European authorities for maritime safety, such as wind and sea state estimates, ice classification, ship navigation through ice-covered waters, detection of navigation irregularities or oil spills as well as the space weather. The Neustrelitz ground station offers data reception in the S, X, and Ka bands as well as data uplink in the S and X bands.

View page in English

디렉터리 기능

전시회 도우미

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

방문 계획 수립

북마크 도구와 이벤트 플래너를 사용해 방문하고자 하는 기업과 관심 있는 제품을 검색하세요. 저장한 모든 항목을 조회할 수 있습니다

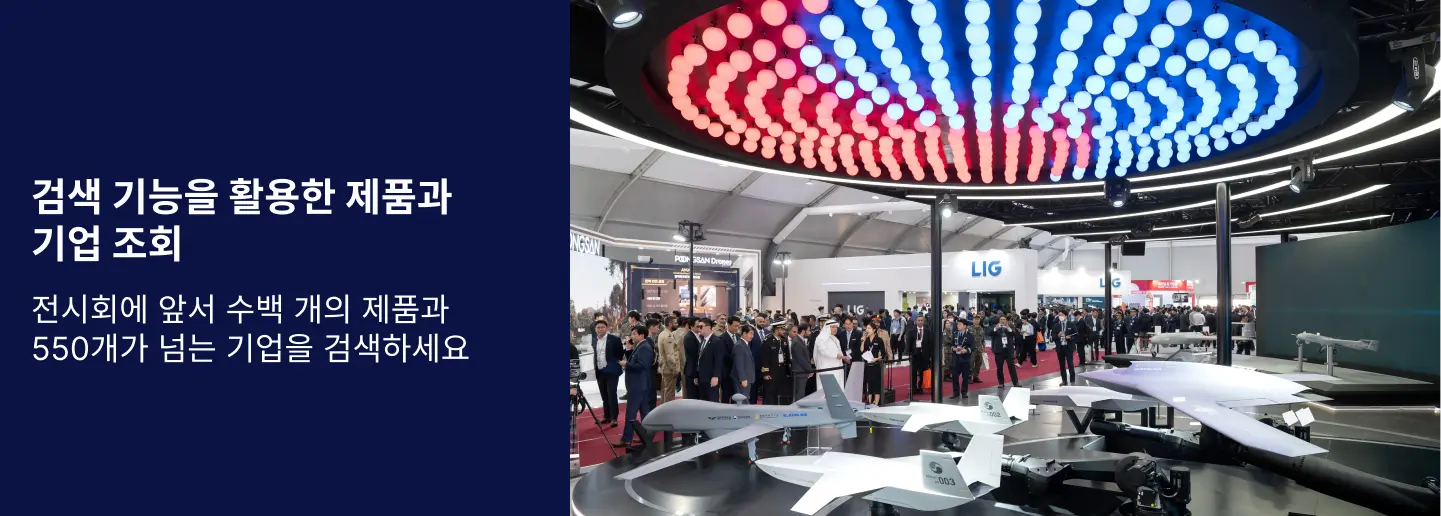

고급 검색

고급 검색 기능을 사용하여 상품, 인물, 기업의 위치를 빠르게 조회할 수 있습니다. 최첨단 기술을 통해 모든 참가사의 정보를 철저히 스캔하여 세밀하고 관련성 있는 정보를 제공합니다

상호작용 가능 평면도

디렉터리를 사용해 전시회를 손쉽게 둘러보세요. 방문하고자 하는 기업의 위치와, 행사장 내 식당, 화장실, 출입구를 평면도에서 찾을 수 있습니다.

플랫폼 내 메시지

플랫폼 상의 전시 참가사와 관람객에게 직접 연락하여 미팅을 신청하거나 추가 정보를 요청하세요.

최신 콘텐츠

기업, 상품, 뉴스, 이벤트

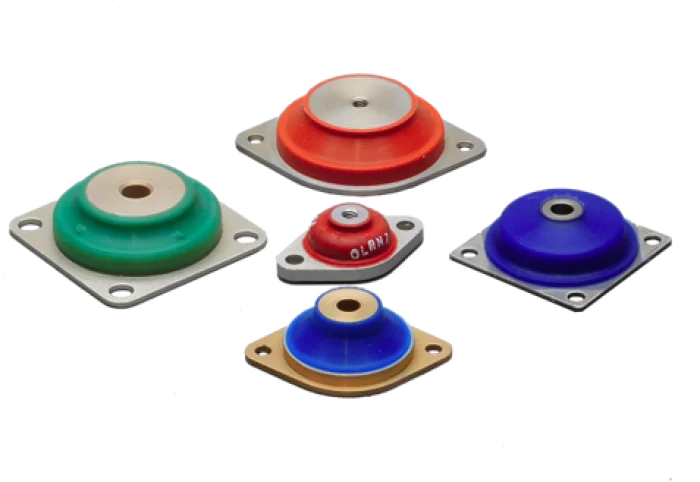

Hanmin International Co., Ltd.

Mounts (LP Mount, RB Mount, Arch Mount, etc.)

Shock Tech designs, develops, manufactures and tests shock attenuation and vibration isolation systems for the most demanding environments.

Customized solutions are provided with application requirements analyzation.

Low Profile & Avionics Mounts are a series of all attitude, mid to high frequency, low profile mounts, used in a variety of applications including airborne avionics, etc.

Bushing Mounts are a series of all attitude, low cost mounts, protecting against both vibration and shock, used in a variety of applications including airborne avionics, etc.

_700.webp)

i3system, inc.

Super MARKOS

Super MARKOS is a new generation T2SL HOT MWIR detector in HD quality. This T2SLHOT detector satisfies requirement of tactical such as long-range surveillance and electro-optical targeting system. The Operating temperature (>130K) will reduce the maintenance cost.

BELL Textron Inc.

Bell 429

Bell 429 - Arrive on the scene quickly, and be ready for anything. Ample cabin space, large doors and adjustable components accommodate your equipment --- and keep your crew comfortable.

TECHSAN ENG

Industrial Borescope ICS2

The operation of robotic inspection systems in an industrial environment requires a reliable control station. The second generation integrated control station -ICS 2- gives operators an all-in-one tool.

Supplied in a rugged hardshell case (Pelicase®), embedded components such as a 21.5-inch touchscreen, high-performance PC or joystick can be selected according to industry standards.

It also boasts a 10-year spare parts guarantee as well as extreme robustness and reliability even in harsh environments.

Simplicity and ease of operation were key when developing ICS 2. The operator connects the robotic platform with one single cable and using the integrated joystick, operation is simple and self-explanatory.

Digital Directory

Digital Directory