한국어로 페이지 보기

Seoul ADEX 2025 Digital Directory

Plan your trip to Seoul ADEX 2025 using our state of the art Digital Directory

Register in seconds with just your email

Directory Features

To help you at the show

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

Plan your trip

Use the bookmarking and event planning tool to research the companies you would like to visit and the products you are interested in finding. You will be able to locate all of your saved companies on our floorplan

Advanced Search

Utilize our advanced search function to quickly locate products, people, and companies. Our state-of-the-art technology thoroughly scans all exhibitor information, delivering precise and relevant results

Interactive Floorplan

Navigate the show effortlessly with our directory. Use the floorplan to locate companies you want to visit and to find your way to onsite restaurants, toilets and site entrances and exits.

On-platform Messaging

Reach out to exhibitors and visitors directly on our platform to set up meetings, or request more information.

Some of our latest content

Companies, Products, News, Events

_700.webp)

KAES

[K2 Main Battle Tank] Main Generator

A Main Generator installed in the K2 main engine that supplies power to the system.

Israel Aerospace Industries (IAI)

Heron MK II

- An updated model of the Heron UAV Strategic and versatile aircraft capable of carrying diverse payloads

- Can reach an altitude of 35,000 feet, speed of 150 knots and remain in the air for 45 consecutive hours

- Wide and strong body structure, allowing for quick and easy maintenance without adding to its weight

- Enables new configurations, as long-range observation sensors and radars

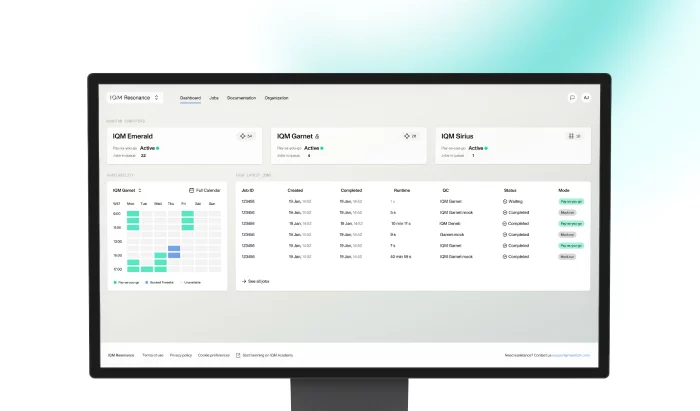

IQM Quantum Computers

IQM Resonance, Cloud service

Every feature designed with transparency and openness in mind. Access enterprise-grade quantum computing with the tools you need to innovate.

SU Optics

ACTUS® CORE-5 Dot Sight

The ACTUS® CORE-5 is the latest development of our Dot Sight lineup. It delivers the same high-end optical performance and legendary durability as our existing CORE Dot Sights, now with enhanced features based on feedback from professional users.

The ACTUS® CORE-5 offers three reticle designs and improved ergonomics, with relocated illumination controls on the top for ambidextrous operation—ensuring seamless adjustments while staying clear of chest rigs and plate carriers when slung.

A dedicated night vision override switch allows for instant adaptation to sudden lighting changes, while the CR2032 battery provides an impressive 20,000-hour runtime at Level 8 brightness.

View page in English

디렉터리 기능

전시회 도우미

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

방문 계획 수립

북마크 도구와 이벤트 플래너를 사용해 방문하고자 하는 기업과 관심 있는 제품을 검색하세요. 저장한 모든 항목을 조회할 수 있습니다

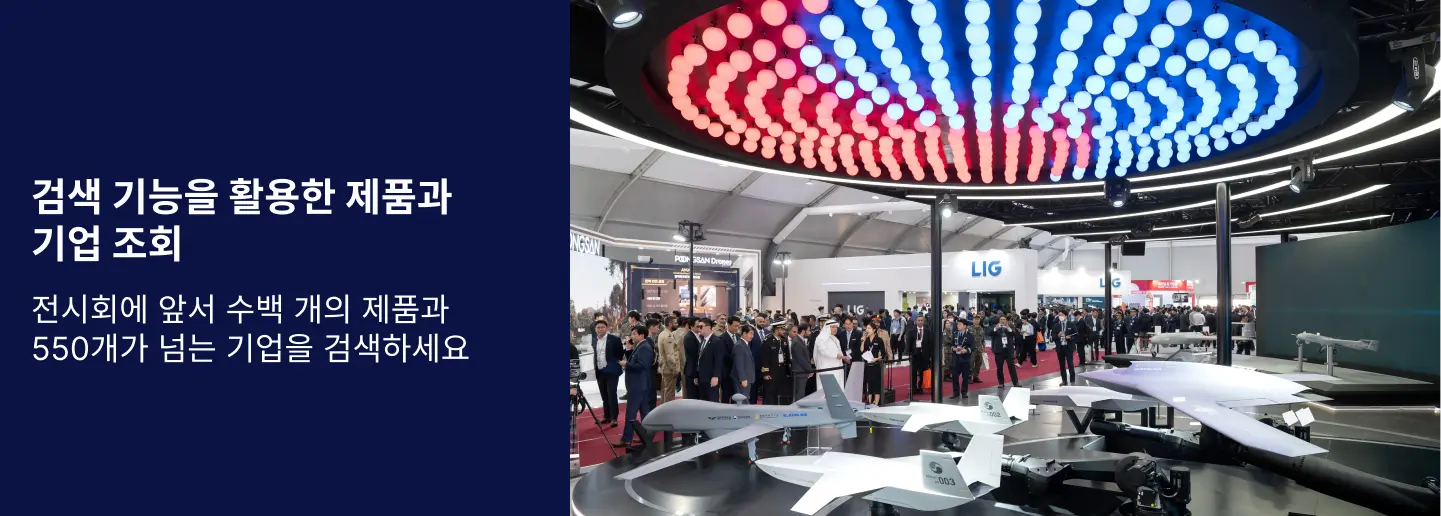

고급 검색

고급 검색 기능을 사용하여 상품, 인물, 기업의 위치를 빠르게 조회할 수 있습니다. 최첨단 기술을 통해 모든 참가사의 정보를 철저히 스캔하여 세밀하고 관련성 있는 정보를 제공합니다

상호작용 가능 평면도

디렉터리를 사용해 전시회를 손쉽게 둘러보세요. 방문하고자 하는 기업의 위치와, 행사장 내 식당, 화장실, 출입구를 평면도에서 찾을 수 있습니다.

플랫폼 내 메시지

플랫폼 상의 전시 참가사와 관람객에게 직접 연락하여 미팅을 신청하거나 추가 정보를 요청하세요.

최신 콘텐츠

기업, 상품, 뉴스, 이벤트

Arizona Commerce Authority

International Trade

The Arizona Commerce Authority's International Trade Program offers Arizona-based companies valuable export services to amplify their trade opportunities in international markets. Services include assistance and trade counseling, getting started, contact facilitation, company background, export leads, educational programs, and more.

Airbility Inc.

AB-U60

The AB-U60 is a 60kg-class vectored-thrust eVTOL aircraft designed for surveillance and emergency logistics. Developed in response to the growing global demand for disaster response and urgent logistics solutions, the AB-U60 can be adapted for a variety of industries, including wildfire monitoring, anti-drone operations, and ship resupply. It combines an advanced fanjet electric propulsion system with a hybrid energy source to achieve high-speed flight and extended endurance.

Airbility’s AB-U60 provides key advantages over competitors, offering high-speed flight of up to 200 km/h and vertical takeoff and landing capabilities for operations in confined spaces. Its low-noise fanjet propulsion system makes it suitable for both urban and suburban missions. The aircraft is also equipped with real-time data analysis and AI-based autonomous flight control systems. These features enable more efficient and safer operations.

Honeywell International

Get Ready with Industrial-Grade Software

The intelligent operations you didn't know existed - and didn't know you needed. Let data be your co-pilot with Honeywell Forge industrial-grade software.Fol...

SAFRAN

MOSKITO TI

MOSKITO TI is a monocular that includes all essential target observation, range finding and geo-location functions, by day and by night, as well as state-of-the-art connectivity to battlefield management solutions. This extremely powerful and light laser rangefinder is operated with four CR123 batteries. Regular software updates keep this device ready for all future mission requirements.

Digital Directory

Digital Directory