한국어로 페이지 보기

Seoul ADEX 2025 Digital Directory

Plan your trip to Seoul ADEX 2025 using our state of the art Digital Directory

Register in seconds with just your email

Directory Features

To help you at the show

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

Plan your trip

Use the bookmarking and event planning tool to research the companies you would like to visit and the products you are interested in finding. You will be able to locate all of your saved companies on our floorplan

Advanced Search

Utilize our advanced search function to quickly locate products, people, and companies. Our state-of-the-art technology thoroughly scans all exhibitor information, delivering precise and relevant results

Interactive Floorplan

Navigate the show effortlessly with our directory. Use the floorplan to locate companies you want to visit and to find your way to onsite restaurants, toilets and site entrances and exits.

On-platform Messaging

Reach out to exhibitors and visitors directly on our platform to set up meetings, or request more information.

Some of our latest content

Companies, Products, News, Events

_700.webp)

Green Optics Co., Ltd.

High-power laser mirror fabrication technology

High-power laser weapons targeting objects at 0.5 ~ 4.0km distances require optical components with sub-nm wavefront error precision. Our Company has successfully developed aspherical polishing and high-power laser coating technologies for Ø300 ~ 550mm optical components through defense project experiences.

measurement technology

1) Laser Induced Damage Threshold(LIDT)

- The evaluation to confirm the durability of optical components is called LIDT (Laser-Induced Damage Threshold), which is defined as "the maximum amount of laser radiation incident on an optical component when the expected probability of damage is zero" (ISO 21254). In other words, it represents the maximum intensity or power of laser that an optical component can withstand, making it a critical requirement in laser weapon systems.

- Our company has established LIDT measurement technology and in-house facilities developed in accordance with ISO 21254 standards. When compared with LIDT test results from domestic and international companies during laser weapon system development, we have demonstrated measurement technology and accuracy that meets or exceeds industry standards. While overseas companies require more than one month for verification processes, our company can immediately provide reliable data through our LIDT system.

2) Cavity Ring Down Spectroscopy(CRDS)

- When the reflectivity is 99.997%, this may not present significant issues in low-power laser applications. However, in high-power laser components, even the 0.05% of light that passes through the optical mirror can cause problems in vulnerable parts of the system, including rear optical instruments, bonded lenses, and control cables. Therefore, measurement and evaluation methods for high-reflectivity optical mirrors are extremely important.

- Currently, the transmittance and reflectance of optical components are generally measured using spectrophotometers, but measuring reflectance levels of 99.5% or higher is not possible with this method. CRDS (Cavity Ring-Down Spectroscopy) technology is required to achieve measurement resolution beyond that of spectrophotometers, and our company has established this system to measure the reflectance of various optical components. This is a critically important technology for responding to high-power laser weapon system development requirements.

BIBUS METALS KOREA

Welding Products

1. Filler Metal

Name Material/Alloy AWS W-No. ISO-No.

Nickel 61 Ni A5.14 ERNi-1 2.4155 SiNi2061

MONEL® 60 Ni-Cu A5.14 ERNiCu-7 2.4377 SNi4060

MONEL® 67 Cu-Ni A5.7 ERCuNi 2.8037 SCu7158

INCONEL® 72 Ni-Cr A5.14 ERNiCr-4 SNi6071

NC 80/20 Ni-Cr 2.4639

INCONEL® 82 Ni-Cr A5.14 ERNiCr-3 2.4806 SNi6082

INCONEL® 622 Ni-Cr-Mo A5.14 ERNiCrMo-10 SNi6022

INCONEL® 625 Ni-Cr-Mo A5.14 ERNiCrMo-3 2.4831 SNi6625

INCO-WELD® 686-CPT Ni-Cr-Mo A5.14 ERNiCrMo-14 SNi6686

INCO-WELD® 725NDUR Ni-Cr-Mo A5.14 ERNiCrMo-15 SNi7725

INCO-WELD® C-276 Ni-Cr-Mo A5.14 ERNiCrMo-4 2.4886 SNi6276

INCONEL® 52 Ni-Cr-Fe A5.14 ERNiCrFe-7 SNi6052

INCONEL® 52M Ni-Cr-Fe A5.14 ERNiCrFe-7A

INCONEL® 92 Ni-Cr-Fe A5.14 ERNiCrFe-6 SNi7092

INCONEL® 617 Ni-Cr-Co-Mo A5.14 ERNiCrCoMo-1 2.4627 SNi6617

NILO® CF36 Ni-Fe

INCOLOY® 65 Ni-Fe-Cr A5.14 ERNiFeCr-1 SNi8065

INCONEL® 718 Ni-Fe-Cr A5.14 ERNiFeCr-2 2.4667 SNi7718

Titanium Grade 1 Ti A5.16-90 ERTi-1

Titanium Grade 2 Ti A5.16-90 ERTi-2

Titanium Grade 5 Ti-Al-V A5.16-90 ERTi-5

Titanium Grade 7 Ti-Pd A5.16-90 ERTi-7

2. Electrodes

Name Material/Alloy AWS W-No. ISO-No.

Nickel 141 Ni A5.11 ENi-1 2.4156 ENi2061

MONEL® 190 Ni-Cu A5.11 ENiCu-7 2.4366 ENi4060

MONEL® 187 Cu-Ni A5.6 ECuNi 2.0838 ECu7158

INCO-WELD® A Ni-Cr-Fe A5.11 ENiCrFe-2 2.4805 ENi6092

INCONEL® 152 Ni-Cr-Fe A5.11 ENiCrFe-7 ENi6152

INCONEL® 182 Ni-Cr-Fe A5.11 ENiCrFe-3 2.4807 ENi6182

INCONEL® 112 Ni-Cr-Mo A5.11 ENiCrMo-3 2.4621 ENi6625

INCONEL® 122 Ni-Cr-Mo A5.11 ENiCrMo-10 ENi6022

INCO-WELD® C-276 Ni-Cr-Mo A5.11 ERNiCrMo-4 2.4887 ENi6276

INCO-WELD® 686CPT Ni-Cr-Mo A5.11 ERNiCrMo-14 ENi6686

INCONEL® 117 Ni-Cr-Co-Mo A5.11 ERNiCrCoMo-1 2.4628 ENi6617

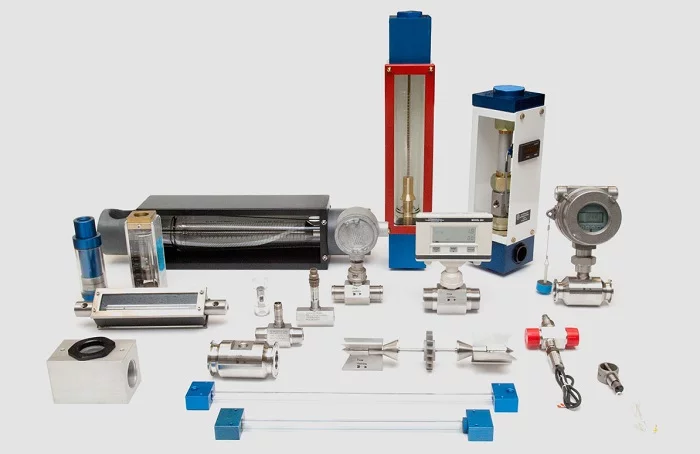

Hydraulics International Inc.

Hydraulics

Hydraulics International, Inc. (HII), headquartered in Chatsworth, California, U.S.A., is a leading worldwide supplier of integrated products, services and support to military forces, aviation and commercial industries, Government agencies and prime contractors. Focused on defense and commercial technology, the Company develops, manufactures and supports a broad range of systems for over one hundred industries as well as mission-critical and military sustainment requirements over the globe. Our extensive design capabilities enable us to produce the most sophisticated technological units known in the Aircraft Ground Support Equipment (AGSE) profession.

_700.webp)

ILSUNG COMPOSITES

Carbon Fiber Composites (CF-SMC)

1. Integrated Production System

Equipped with in-house CF-SMC compression molding equipment, we provide a complete one-stop solution—from sheet production to final composite molding—tailored to customer requirements. This ensures both exceptional quality and production efficiency. In line with ESG management, we also utilize our proprietary recycled carbon fiber technology to recycle CFRP waste generated during CF-SMC production.

2. Moldability & Productivity

ILSUNG’s carbon fiber SMC technology offers superior moldability compared to conventional continuous CFRP and aluminum. With a rapid curing speed of about 1 minute per 1 mm thickness, it enables high-speed, mass production. Complex and precise geometries can be molded reliably, delivering strong competitiveness for both simple and highly engineered components.

3. Exceptional Lightweight Performance

CF-SMC has a lower density than aluminum castings while maintaining high mechanical strength, delivering the optimal lightweight solution for industries where weight reduction is critical.

4. Balanced Performance

This technology not only achieves lightweight properties but also ensures a well-balanced combination of mechanical strength, corrosion resistance, dimensional stability, and durability. It maintains stable performance under extreme environments and repeated loads, making it highly suitable for automotive, aerospace, and defense applications where reliability is critical.

5. Cost Competitiveness

Compared to CFRP, it provides a lower-cost structure and high-speed molding capability, ensuring excellent price competitiveness. This significantly improves cost efficiency in industries that demand large-scale production—such as automotive, aerospace, and defense—and strengthens its growth potential within the composites market.

View page in English

디렉터리 기능

전시회 도우미

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

방문 계획 수립

북마크 도구와 이벤트 플래너를 사용해 방문하고자 하는 기업과 관심 있는 제품을 검색하세요. 저장한 모든 항목을 조회할 수 있습니다

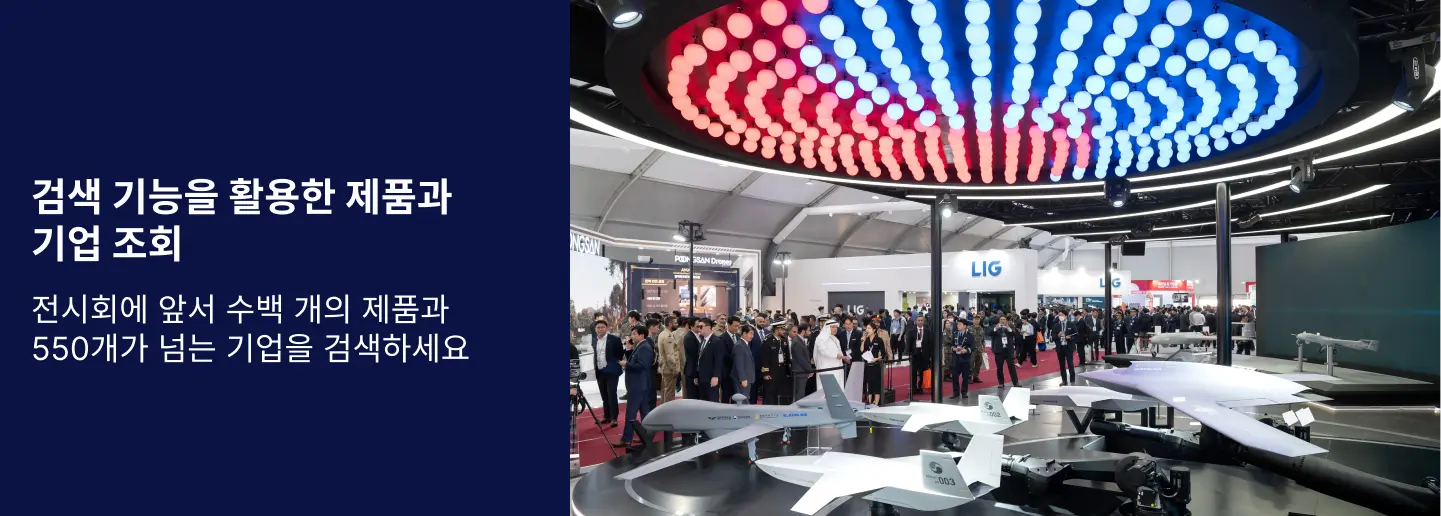

고급 검색

고급 검색 기능을 사용하여 상품, 인물, 기업의 위치를 빠르게 조회할 수 있습니다. 최첨단 기술을 통해 모든 참가사의 정보를 철저히 스캔하여 세밀하고 관련성 있는 정보를 제공합니다

상호작용 가능 평면도

디렉터리를 사용해 전시회를 손쉽게 둘러보세요. 방문하고자 하는 기업의 위치와, 행사장 내 식당, 화장실, 출입구를 평면도에서 찾을 수 있습니다.

플랫폼 내 메시지

플랫폼 상의 전시 참가사와 관람객에게 직접 연락하여 미팅을 신청하거나 추가 정보를 요청하세요.

최신 콘텐츠

기업, 상품, 뉴스, 이벤트

Intergravity Technologies

20N bipropellant thruster

InterGravity Technologies has developed a 20 Newton-class bipropellant thruster designed for orbital transfer vehicles (OTVs), lunar hoppers, and micro-spacecraft requiring high efficiency, reliability, and reusability. The thruster operates with green propellants (C₂H₆, N₂O), providing both environmental compatibility and storability advantages.

Key Features

-Thrust Level : 20N

-Specific Impulse : > 295s in vacuum

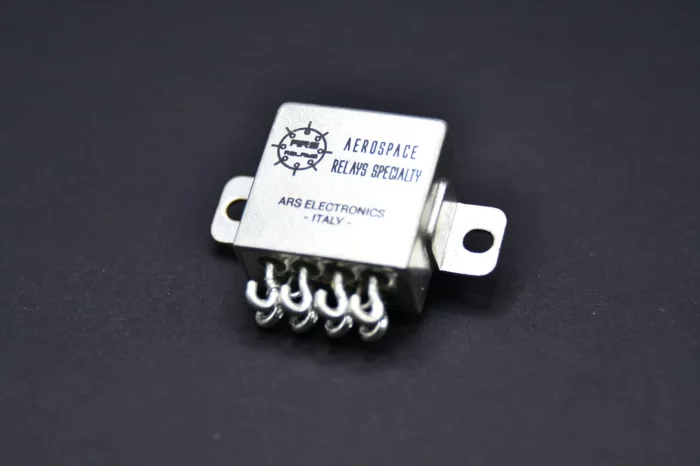

ARS ELECTRONICS S.r.l.

RELAYS

ELECTROMECHANICAL RELAYS

EO System

Thermal Weapon Sight

SURI-III is a super multi functioning sight, optimizing firing capabilities for Caliber 50(M2) and AGL(MK19)in the day and night time condition. It could be supported by HMD for User’s shooting position in convenience and for saving Force’s lives.

Thermal Camera + Day Camera + LRF + Red Dot Sight + Wireless Goggle + Customized Reticle + Wide Screen presents in One Device

EO System

Multi-Function Observation Device

THETIS-C is a compact multifunction thermal imaging system that provides soldiers with an advanced, light weight solution for day and night reconnaissance, surveillance and forward observation purposes.

It also gives the blue forces a real-time target acquisition and target coordinate calculation capabilities.

Thermal Camera + Day CMOS Camera + Direct View Optic + Laser Range Finder + Digital Magnetic Compass + GPS

Digital Directory

Digital Directory