한국어로 페이지 보기

Seoul ADEX 2025 Digital Directory

Plan your trip to Seoul ADEX 2025 using our state of the art Digital Directory

Register in seconds with just your email

Directory Features

To help you at the show

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

Plan your trip

Use the bookmarking and event planning tool to research the companies you would like to visit and the products you are interested in finding. You will be able to locate all of your saved companies on our floorplan

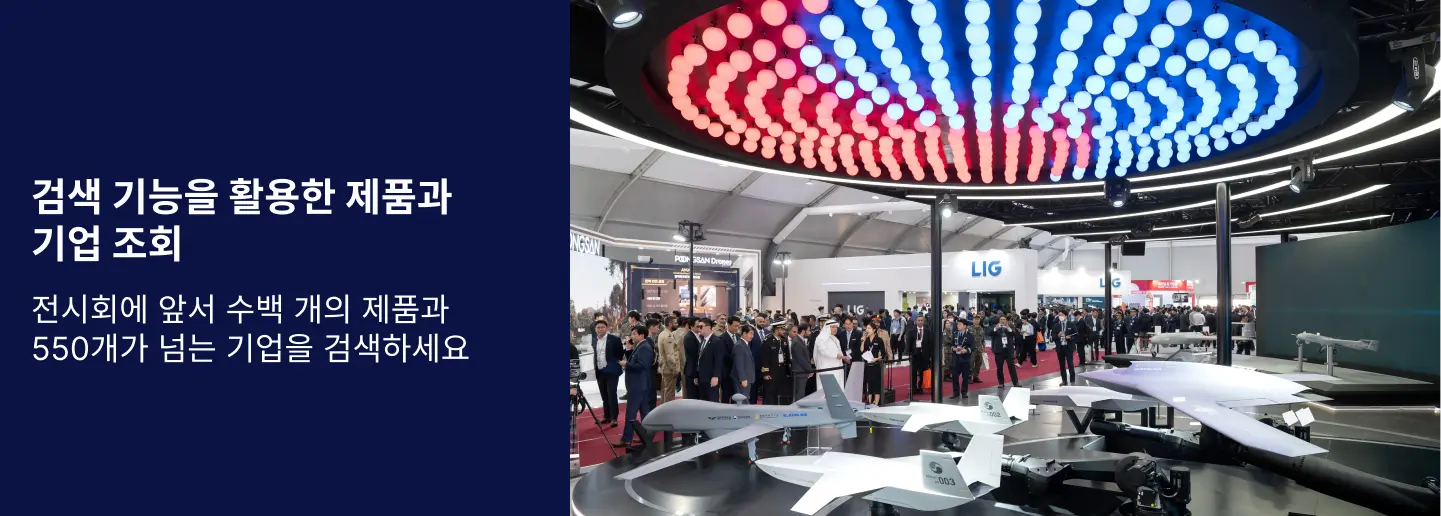

Advanced Search

Utilize our advanced search function to quickly locate products, people, and companies. Our state-of-the-art technology thoroughly scans all exhibitor information, delivering precise and relevant results

Interactive Floorplan

Navigate the show effortlessly with our directory. Use the floorplan to locate companies you want to visit and to find your way to onsite restaurants, toilets and site entrances and exits.

On-platform Messaging

Reach out to exhibitors and visitors directly on our platform to set up meetings, or request more information.

Some of our latest content

Companies, Products, News, Events

DOC - International Trade Administration

Find Buyers and Partners

For small U.S. businesses, finding international buyers and partners doesn't always come easy. First, decide how your business should enter the market and read our articles for key considerations. Then get support for your efforts with services from the U.S. Commercial Service.

MKS Ophir

Widest Collection of Long-Range LWIR & MWIR IR Zoom Lenses for Observation Systems

Experience unparalleled clarity and precision across the full zoom range with Ophir's MWIR cooled and LWIR uncooled long-range IR zoom lenses. Providing MTF close to the diffraction limit, these lenses excel in long detection, recognition, and identification (DRI) ranges, making them ideal for diverse commercial, surveillance, and homeland security applications. Available in various FPA formats, including High Definition XGA and SXGA.

Key characteristics:

• High MTF

• Accurate thru-zoom boresight

• Focus and F# maintained through the full zoom range

• Rugged design for toughest environments

• Zoom up to X30

• Fast FOV change

• Diffraction-limited optical design

• Athermal compensation

• High durability, low reflection hard carbon AR coating

Contact us to set a meeting at ADEX Seoul for further discussion.

Korea Aerospace Industries

Korea Space Launch Vehicle

KAI participates in the system integration of the KSLV-II and development of

its first-stage propellant tank while trying to secure the technology of Space Launch Vehicle.

TAEKYUNG ELEC. Co., LTD.

Multi-purpose Modular Lighting Broadcast Drone

1. Ultra-high Performance LED Searchlight (53,000lm+ max)

- Designed with heat sink optimization via thermal analysis for extended illumination.

2. Powerful Broadcasting System (100dB)

3. AI Algorithm for Automatic Object Recognition and Tracking based on Jetson Platform

4. Equipped with EO/IR Cameras for All-Weather Surveillance and Precise Target Identification

5. Hybrid Wired/Wireless System for Enhanced Flight Endurance: Wired Power System, Automatic Wired Detachment Module

View page in English

디렉터리 기능

전시회 도우미

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

방문 계획 수립

북마크 도구와 이벤트 플래너를 사용해 방문하고자 하는 기업과 관심 있는 제품을 검색하세요. 저장한 모든 항목을 조회할 수 있습니다

고급 검색

고급 검색 기능을 사용하여 상품, 인물, 기업의 위치를 빠르게 조회할 수 있습니다. 최첨단 기술을 통해 모든 참가사의 정보를 철저히 스캔하여 세밀하고 관련성 있는 정보를 제공합니다

상호작용 가능 평면도

디렉터리를 사용해 전시회를 손쉽게 둘러보세요. 방문하고자 하는 기업의 위치와, 행사장 내 식당, 화장실, 출입구를 평면도에서 찾을 수 있습니다.

플랫폼 내 메시지

플랫폼 상의 전시 참가사와 관람객에게 직접 연락하여 미팅을 신청하거나 추가 정보를 요청하세요.

최신 콘텐츠

기업, 상품, 뉴스, 이벤트

Telcom International

Ducommun

Founded in 1849, Ducommun is the oldest company in California, USA. Currently located in Carson, near Los Angeles, the company began as a hardware supply store in Los Angeles during the California Gold Rush and now designs and manufactures aerospace, RF coaxial switches, switch matrices, and millimeter-wave components.

- Microwave Products (available from DC to 46GHz SPST through the SP10T range)

- Switch Matrices (product design and customization to meet individual customer requirements)

- Ducommun RF products cover the DC range up to 110GHz

- Coaxial Switches available up to 40GHz

- Low Noise / High Power RF Products

- Space-Grade Products

BAE Systems

Cyber Resilience Platform Intrusion Detection

Given the risks to U.S. armed forces personnel and other assets, shielding defense community computers, comm systems, and electronic platforms with outdated "Defense in Depth" cyber security is less than optimal. Today, state-sponsored and other cyber attacks can often bypass traditional security defenses, remain undetected for weeks or months, and be hard to track once noticed.

_700.webp)

K-PA Inc.

KX1-3046

The KX1-3046 is an X-band high-power MMIC amplifier fabricated on the GaN-on-SiC process. It operates from 8.0 – 10.5 GHz and typically provides 30W saturated output power with power-added efficiency of 46%.

The KX1-3046 can support military and commercial radar systems. It is matched to 50Ω with integrated DC blocking capacitors on both RF input and output ports.

The KX1-3046 is 100% DC and RF tested on-wafer. It is available in chip form.

**Key Features**

- Frequency Range: 8.0-10.5GHz

- Small Signal Gain: 28dB

- High Pout: 30W

- High PAE: 46%

- DC bias: Vd=28V @Idq=0.6A

- Pulsed Vg: PW=100µs, DC=10%

- Chip size: 2.95x3.1x0.1mm

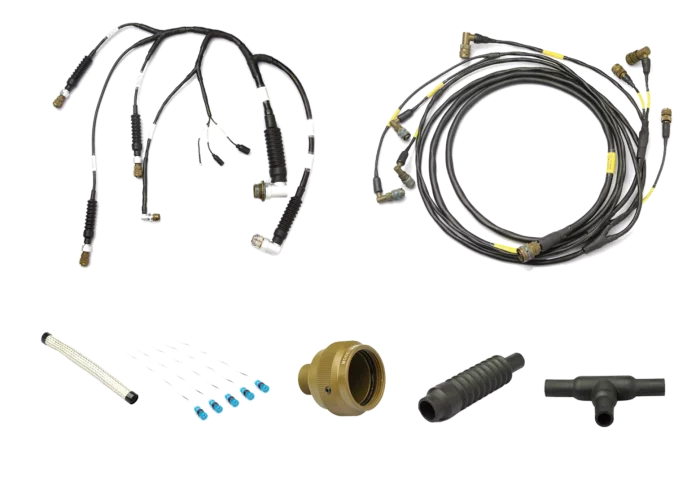

Yeonhab Precision

Cable Assembly

This product is designed and manufactured specific for customers’ demand and includes the power supply and signal transmission parts of weapon systems in all fields of the Korean army, navy, and air force, as well as for the civilian field. As all parts are localized and assembled into finished products, they are ensured of best performance and reliable quality.

Digital Directory

Digital Directory