한국어로 페이지 보기

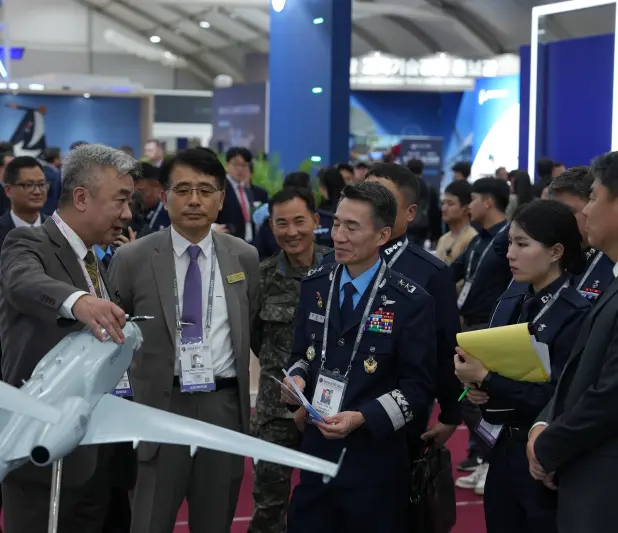

Seoul ADEX 2025 Digital Directory

Plan your trip to Seoul ADEX 2025 using our state of the art Digital Directory

Register in seconds with just your email

Directory Features

To help you at the show

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

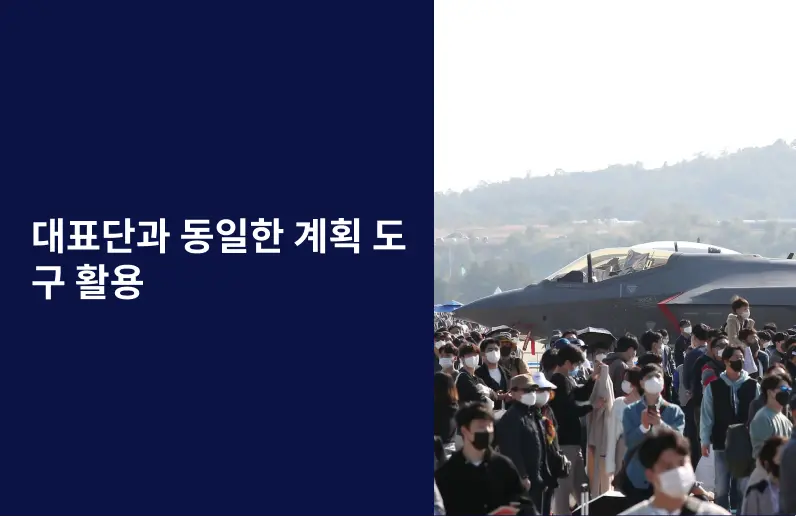

Plan your trip

Use the bookmarking and event planning tool to research the companies you would like to visit and the products you are interested in finding. You will be able to locate all of your saved companies on our floorplan

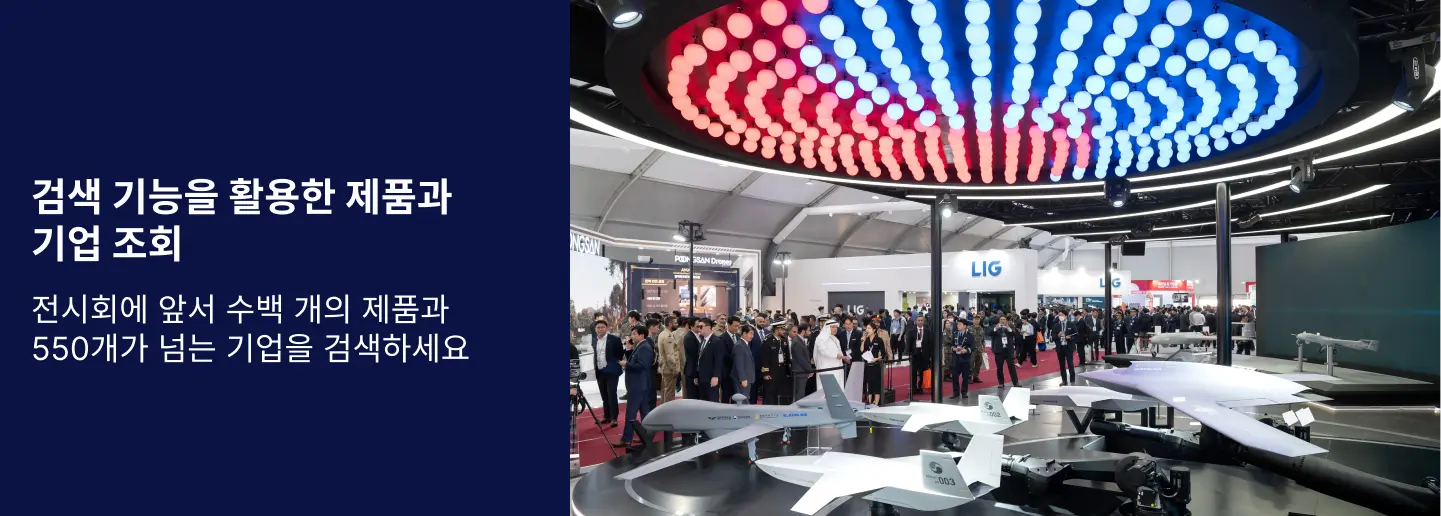

Advanced Search

Utilize our advanced search function to quickly locate products, people, and companies. Our state-of-the-art technology thoroughly scans all exhibitor information, delivering precise and relevant results

Interactive Floorplan

Navigate the show effortlessly with our directory. Use the floorplan to locate companies you want to visit and to find your way to onsite restaurants, toilets and site entrances and exits.

On-platform Messaging

Reach out to exhibitors and visitors directly on our platform to set up meetings, or request more information.

Some of our latest content

Companies, Products, News, Events

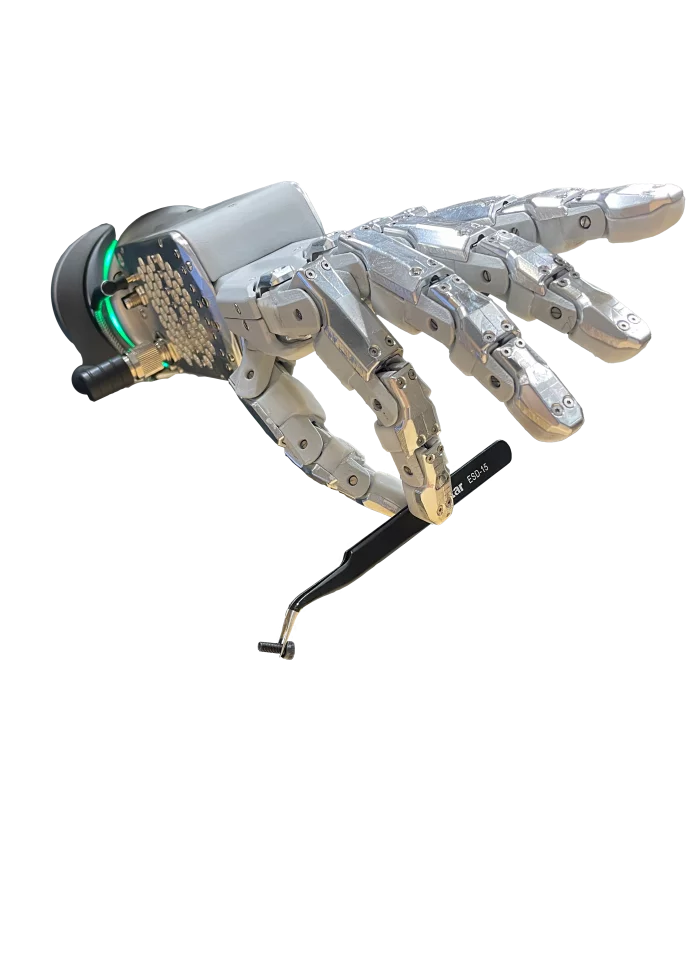

Sarcomere Dynamics Inc.

ARTUS Lite

The ARTUS Lite’s prowess extends to tele-operation scenarios, particularly within military, nuclear, and bio-pharma applications, where an end-effector that operates with both finesse and confidence is crucial. It provides a safe and precise solution for remote manipulation in hazardous or inaccessible environments, proving vital in environments where the safety and replacement of manual labor are urgent concerns. It excels in machine tending and pick-and-place automation within greenhouses, warehouses, and recycling facilities, enhancing productivity while prioritizing worker safety.

_700.webp)

DusiTech Co., Ltd.

GNSS Receiver

[LEO GNSS-R]

Satellite : LEO

RF Characteristics : GPS L1/L5, Galileo E1/E5a(option)

Accuracy : Position ≤ 10m(3DRMS), Velocity : ≤ 1m/s

Raw Data Accuracy : Pseudo-Range : 1m(RMS)

Carrier-Phase : 10mm(RMS)

Data Output Rate : 1Hz

1PPS Accuracy : Sync to GPS Time Data < 1us

(1PPS Accuracy < 1.5us)

TTFF : Cold Start ≤ 20min / Warm Start ≤ 10min

Dara Interface : MIL-STD-1553B, RS-422(Data Interface)

[GEO GNSS-R]

Satellite : GEO

RF Characteristics : GPS L1/L2C/L5, Galileo E1

Accuracy : Position :: ≤ 30m(3DRMS), Velocity : ≤ 1m/s

Raw Data Accuracy : Pseudo-Range : 1m(RMS)

Carrier-Phase : 10mm(RMS)

Data Output Rate : 1Hz

1PPS Accuracy : 2us(RMS)/Sync to GPS Time Data

TTFF : Cold Start ≤ 45min / Warm Start ≤ 20min

Dara Interface : MIL-STD-1553B

EEE Parts : ITAR Free Parts

_700.webp)

ACEWAVETECH

Radar Signal Generator

'The simulators offer variety of simulation capabilities; including Radar Warning Receivers, Missile Warning Receivers and other Electronic Warfare (EW) Receivers.

KPC Metal (KPCM)

Aerospace & Defense

Our products serve the clients in military and aerospace industries, who require high performance with strength and ability to perform at extreme temperatures and pressures.

View page in English

디렉터리 기능

전시회 도우미

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

방문 계획 수립

북마크 도구와 이벤트 플래너를 사용해 방문하고자 하는 기업과 관심 있는 제품을 검색하세요. 저장한 모든 항목을 조회할 수 있습니다

고급 검색

고급 검색 기능을 사용하여 상품, 인물, 기업의 위치를 빠르게 조회할 수 있습니다. 최첨단 기술을 통해 모든 참가사의 정보를 철저히 스캔하여 세밀하고 관련성 있는 정보를 제공합니다

상호작용 가능 평면도

디렉터리를 사용해 전시회를 손쉽게 둘러보세요. 방문하고자 하는 기업의 위치와, 행사장 내 식당, 화장실, 출입구를 평면도에서 찾을 수 있습니다.

플랫폼 내 메시지

플랫폼 상의 전시 참가사와 관람객에게 직접 연락하여 미팅을 신청하거나 추가 정보를 요청하세요.

최신 콘텐츠

기업, 상품, 뉴스, 이벤트

ACEWAVETECH

EW Receiver Test System

- RWR receiver inspection and antenna performance measurement

- EW receiver inspection

- Check the azimuth and signal power of the RWR receiver

Ultronics

SDI170 Tactical Grade Inertial Measurement Unit

EMCORE’s SDI170 IMU is designed as a performance-compatible inertial system that is form, fit, and functional with a legacy RLG-based IMU product, but with superior overall performance, versatility, and a significantly higher MTBF (Mean Time Before Failure) rating over ruggedized environments. The tactical performance of the SDI170 IMU is based on EMCORE’s mature, proven, dependable and accurate quartz MEMS inertial sensor technology in our SDI500 tactical-grade IMU. EMCORE’s quartz technology enables repeatable high-volume production of precisely machined sensor structures combined with the inherent large signal output and thermal stability of quartz materials.

The SDI170 IMU is designed for demanding, mission-critical, rugged environments and ideal for continuous use applications with no wear-out components, highly linear accelerometer performance and longer life compared to competing alternatives. It is constructed with EMCORE’s latest generation quartz gyros, quartz accelerometers, and high-speed signal processing to achieve outstanding precision performance. The solid-state quartz sensors and hermetically sealed IMU construction provide reliable MTBF and a 20-year operating and storage life. Continuous Built-in Test (BIT), configurable communications protocols, electromagnetic interference (EMI) protection and flexible input power compatibility make the SDI170 IMU easy to use in a wide range of higher-order integrated commercial and defense system applications.

_700.webp)

SeA Electronics Co., Ltd.

Coaxial cable

Suitable for critical military systems such as aerospace, defense, communications, and electronic warfare.

Maintains performance under harsh conditions such as high and low temperatures, moisture, vibration, shock, and chemicals

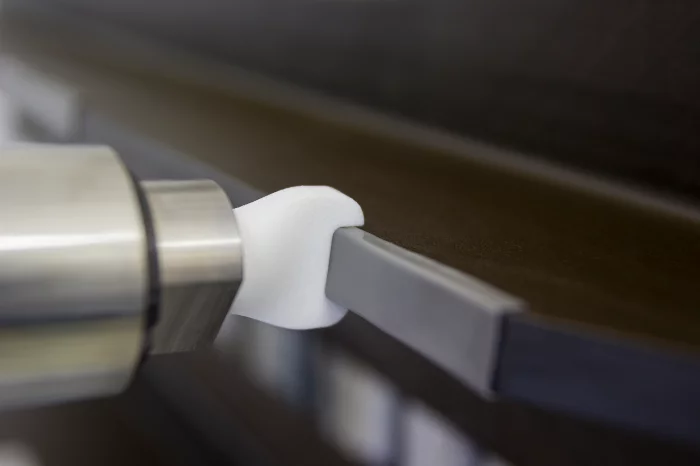

ViscoTec Pumpen- u. Dosiertechnik GmbH

Edge Sealing for Structural Components

Wing shells, side shells and fuselage sections are usually made of carbon fibre composites and glued together during the production process. With many components, a groove or an open edge remains after the bonding process, which must be filled or sealed.

A modified two-component epoxy resin is often mixed and then applied manually. This often entails long production times and complex quality controls. Equally high material costs due to the processing of materials from cartridges.

ViscoTec defies short pot life and materials that are difficult to handle: Thanks to a coherent overall system from material removal to material application, this process can be automated. The two components are taken separately from cartridges, hobbocks or drums and fed via hose lines to a two-component dosing system. Only at the very end of the process they are mixed in a static mixing tube and applied to the substrate (e.g. via a nozzle). The process is controlled and monitored by pressure sensors.

Digital Directory

Digital Directory