한국어로 페이지 보기

Seoul ADEX 2025 Digital Directory

Plan your trip to Seoul ADEX 2025 using our state of the art Digital Directory

Register in seconds with just your email

Directory Features

To help you at the show

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

Plan your trip

Use the bookmarking and event planning tool to research the companies you would like to visit and the products you are interested in finding. You will be able to locate all of your saved companies on our floorplan

Advanced Search

Utilize our advanced search function to quickly locate products, people, and companies. Our state-of-the-art technology thoroughly scans all exhibitor information, delivering precise and relevant results

Interactive Floorplan

Navigate the show effortlessly with our directory. Use the floorplan to locate companies you want to visit and to find your way to onsite restaurants, toilets and site entrances and exits.

On-platform Messaging

Reach out to exhibitors and visitors directly on our platform to set up meetings, or request more information.

Some of our latest content

Companies, Products, News, Events

Hyundai Steel

Composite parts for AAM & Aircraft

We are Hyundai Steel, a member of Hyundai Motor Group, developing advanced composite parts for aircraft and AAM, with a focus on both structural and exterior applications. Using our rapid press-forming process, we can manufacture high-quality components in under 30 minutes, enabling faster production cycles and reliable performance. We also bring prior experience in small-scale production of automotive composite parts, strengthening our expertise across industries. If you are seeking to enhance the productivity of your composite parts, please feel free to contact us anytime for collaboration.

Sangdo Electronics co.,Ltd

L Series

The L Series comes with frames in various lengths to accommodate a variety of module combinations. The frames range from a basic frame with just 2 side rails and 2 end caps, to more complex versions with jackscrews, backshells, cable clamps, etc.

Sungsan Electronic

(C-UAS) FEM

< Frequency Range >

● LB-400: 400 ~ 460MHz

● LB-900: 800~928MHz

● MB-1500: 1300~1500MHz

● MB-2400: 2400 ~ 2500MHz

● HB-5.2: 5150 ~ 5250MHz

● HB-5.8: 5725 ~ 5875MHz

< TX path output Power (at antenna port) >

● Normal mode: 35dBm [min]

● On each antenna port 2x 35dBm

● Interference mode: 40dBm [min]

< TX path maximum Input Power >

● +20 dBm

< RX path Gain >

● 25dB typ.

< RX path Noise figure >

● Low bands: 3dB max.

● High bands 3.5dB max.

< RX path IIP3 >

● -10dBm typ.

< RX IP1dB compression point >

● 15dBm typ.

< Power Supply >

● +24V ± 1 Vdc

폭발물처리로봇 WT모터1_700.webp)

KAES

[Explosive Ordnance Disposal Robot] WT Motor

Electric motor used to drive the joint (WT axis) of the Explosive Ordnance Disposal (EOD) Robot.

View page in English

디렉터리 기능

전시회 도우미

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

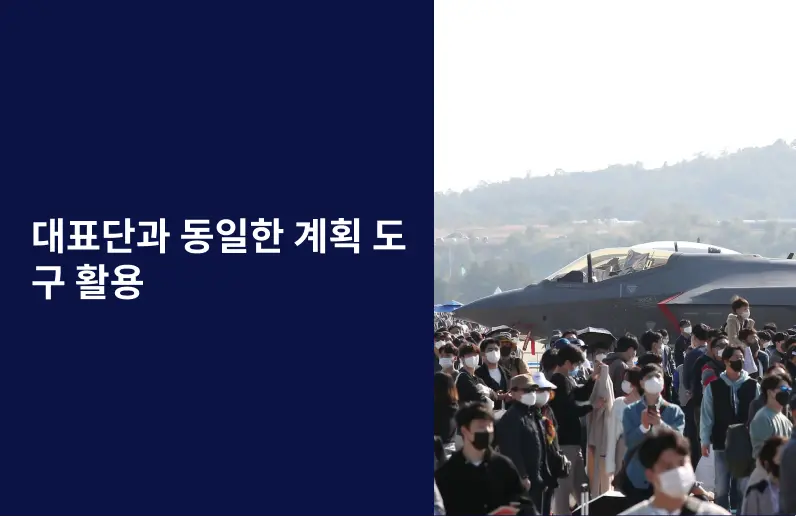

방문 계획 수립

북마크 도구와 이벤트 플래너를 사용해 방문하고자 하는 기업과 관심 있는 제품을 검색하세요. 저장한 모든 항목을 조회할 수 있습니다

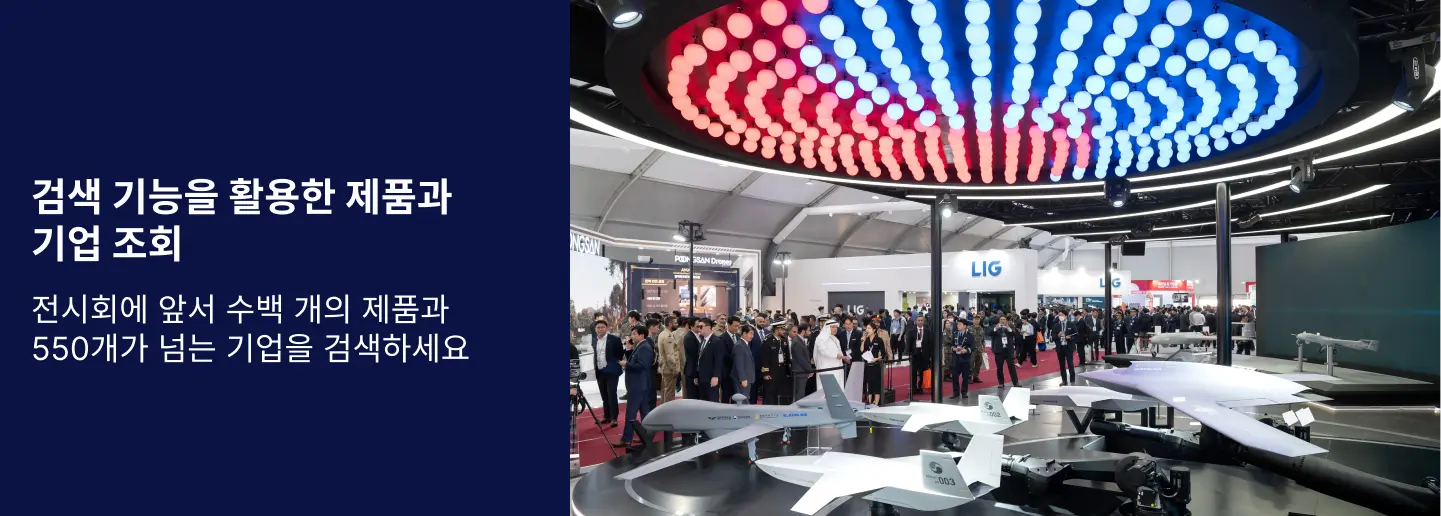

고급 검색

고급 검색 기능을 사용하여 상품, 인물, 기업의 위치를 빠르게 조회할 수 있습니다. 최첨단 기술을 통해 모든 참가사의 정보를 철저히 스캔하여 세밀하고 관련성 있는 정보를 제공합니다

상호작용 가능 평면도

디렉터리를 사용해 전시회를 손쉽게 둘러보세요. 방문하고자 하는 기업의 위치와, 행사장 내 식당, 화장실, 출입구를 평면도에서 찾을 수 있습니다.

플랫폼 내 메시지

플랫폼 상의 전시 참가사와 관람객에게 직접 연락하여 미팅을 신청하거나 추가 정보를 요청하세요.

최신 콘텐츠

기업, 상품, 뉴스, 이벤트

PEI-Genesis

Aviation Safety Products

Vitzro Cell

Ampoule Reserve Battery

Lithium based Ampoule Battery has high reliability, wide temperature range (-43°C to +70°C), long shelf life (20 years or more) with short activation time. We service the optimized and customized solutions to the customers worldwide. *Applications - Electronic fuzes - Calibers - Naval/Artillery Gun - Multiple Launch Rocket System - Remote Anti-Armor Mine System

_700.webp)

CTLA

로켓발사대(Rocket Launcher)

From the rocket launcher to its upper assembly, the bomb rack unit, completing a full weapon system as one set.

The rocket launcher is a weapon system independently designed to launch guided missiles or rockets through 7-tube and 19-tube launchers, enabling both single and multiple firings.

Through its development, independence of the weapon system has been secured, and structural stability has been achieved by applying a design that considers aircraft vibration and aerodynamic effects.

In addition, it is equipped with the capability to receive the system’s firing signal and ignite the rocket.

Based on the successful development in 2017 of the 7-tube 2.75-inch rocket launcher assembly for helicopters, the company is now independently developing upgraded versions of the 7-tube and 19-tube rocket launcher assemblies.

Through this effort, we are securing scalability for application to next-generation helicopters and UAV systems.

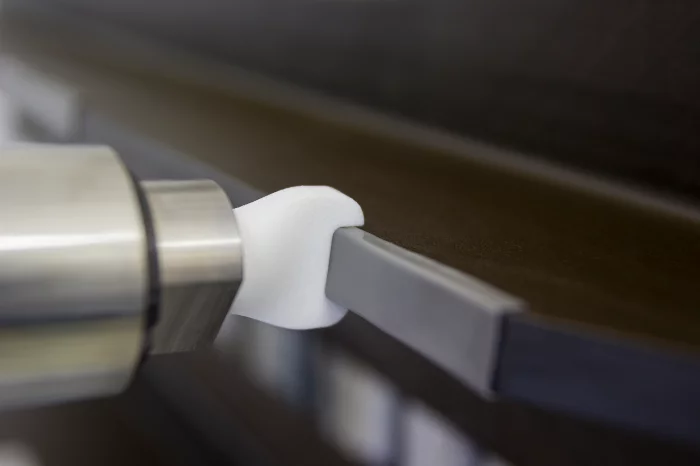

ViscoTec Pumpen- u. Dosiertechnik GmbH

Edge Sealing for Structural Components

Wing shells, side shells and fuselage sections are usually made of carbon fibre composites and glued together during the production process. With many components, a groove or an open edge remains after the bonding process, which must be filled or sealed.

A modified two-component epoxy resin is often mixed and then applied manually. This often entails long production times and complex quality controls. Equally high material costs due to the processing of materials from cartridges.

ViscoTec defies short pot life and materials that are difficult to handle: Thanks to a coherent overall system from material removal to material application, this process can be automated. The two components are taken separately from cartridges, hobbocks or drums and fed via hose lines to a two-component dosing system. Only at the very end of the process they are mixed in a static mixing tube and applied to the substrate (e.g. via a nozzle). The process is controlled and monitored by pressure sensors.

Digital Directory

Digital Directory