한국어로 페이지 보기

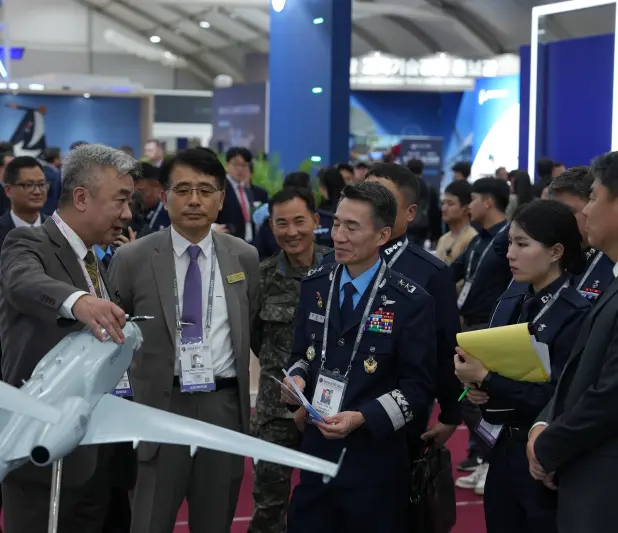

Seoul ADEX 2025 Digital Directory

Plan your trip to Seoul ADEX 2025 using our state of the art Digital Directory

Register in seconds with just your email

Directory Features

To help you at the show

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

Plan your trip

Use the bookmarking and event planning tool to research the companies you would like to visit and the products you are interested in finding. You will be able to locate all of your saved companies on our floorplan

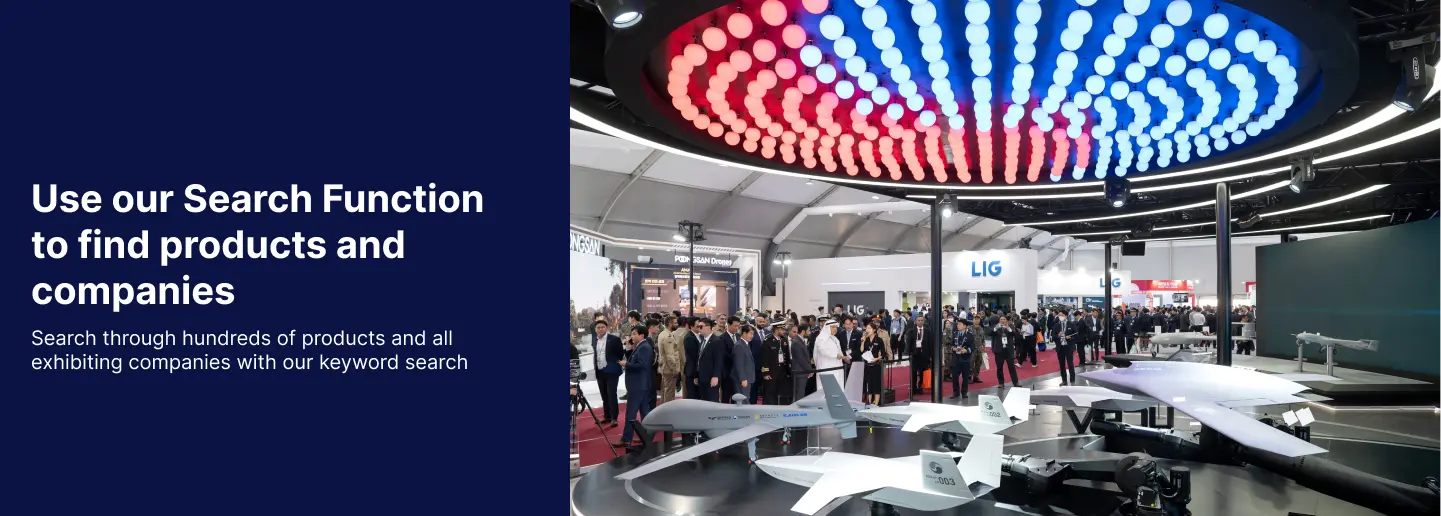

Advanced Search

Utilize our advanced search function to quickly locate products, people, and companies. Our state-of-the-art technology thoroughly scans all exhibitor information, delivering precise and relevant results

Interactive Floorplan

Navigate the show effortlessly with our directory. Use the floorplan to locate companies you want to visit and to find your way to onsite restaurants, toilets and site entrances and exits.

On-platform Messaging

Reach out to exhibitors and visitors directly on our platform to set up meetings, or request more information.

Some of our latest content

Companies, Products, News, Events

_700.webp)

DUKSAN AETHERCT Co., Ltd.

Hydrogen Tube Trailers

DS AETHER CT provides various industrial Gas Tube Skids such as Hydrogen (H2), Helium (He), Neon (Ne), Nitrogen (N2) and Argon (Ar) as well as CNG. The working pressure is set to national requirements or customer's demands. The color of the jumbo tubes and skid frames follows ISO color codes or the designations of customers.

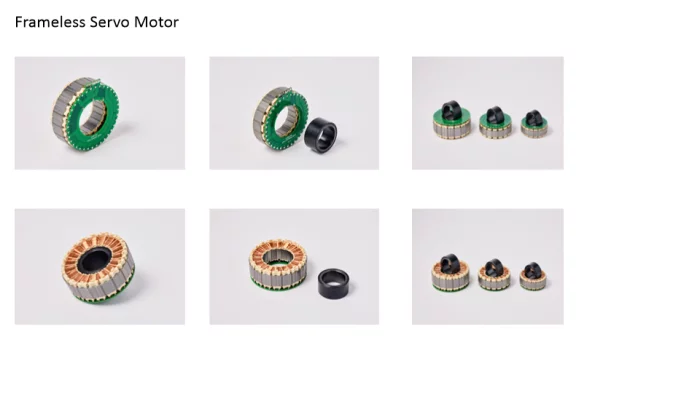

KOMOTEK CO., LTD.

Frameless servo motor

Various line up, high torque frameless motor capable of precise speed and position control. Application areas are Collaborative robots, Dog Horse robots.

.jpg)

Haigh-Farr, Inc.

Antennas

Haigh-Farr specializes in the design, manufacture, and testing (electrical and environmental) of conformal and non-conformal antennas. As a leader in the aerospace industry, our antennas are found on the latest high-performance airborne and space vehicles. Haigh-Farr is well known for its reliable, high-quality range of customizable and off-the-shelf solutions.

BAE Systems

Cabin Management Systems

Using a data storage module and a series of high-speed switches, our solution offers expandable memory up to 64 TB and high-speed processing power. Along with our attendant control panel, designed to reduce the crew's workload, we offer a complete end-to-end solution.

View page in English

디렉터리 기능

전시회 도우미

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

방문 계획 수립

북마크 도구와 이벤트 플래너를 사용해 방문하고자 하는 기업과 관심 있는 제품을 검색하세요. 저장한 모든 항목을 조회할 수 있습니다

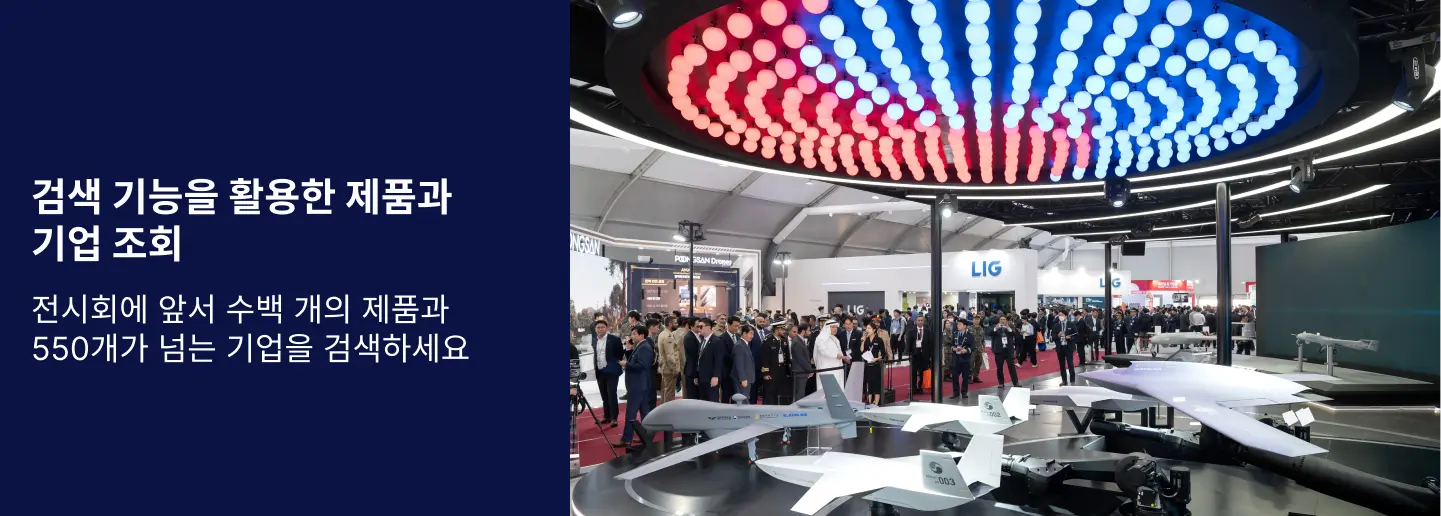

고급 검색

고급 검색 기능을 사용하여 상품, 인물, 기업의 위치를 빠르게 조회할 수 있습니다. 최첨단 기술을 통해 모든 참가사의 정보를 철저히 스캔하여 세밀하고 관련성 있는 정보를 제공합니다

상호작용 가능 평면도

디렉터리를 사용해 전시회를 손쉽게 둘러보세요. 방문하고자 하는 기업의 위치와, 행사장 내 식당, 화장실, 출입구를 평면도에서 찾을 수 있습니다.

플랫폼 내 메시지

플랫폼 상의 전시 참가사와 관람객에게 직접 연락하여 미팅을 신청하거나 추가 정보를 요청하세요.

최신 콘텐츠

기업, 상품, 뉴스, 이벤트

PBS GROUP

PBS APU SPARK40

We are an EASA-certified APU manufacturer. To date, we have installed more than 7,000 PBS APUs.

This APU includes completely new combustion chamber, new control unit allowing allow non-operating altitude up to 8,000 m AMSL.

Redesigned fuel system.

Continuous operation for 6 hours.

Exceptional reliability. Start up to 6,000 m

Kia

New 2½ Ton Medium Cargo Truck

Kia newly developed 2½ ton Medium Cargo Truck to fit all- battlefield environments with the best driving performance and durability and survivability based on its long-accumulated military and commercial vehicles technology.

280 – HP Diesel Engine

Mounting commercial high-efficiency and high-hoursepower engines onto behicles for tracking capability, cold starting, and electromagnetic wave shielding adequate for military applications

Automatic transmission

Improves the convenience of operating the vehicle, and prevents the engine from shutting down and the vehicle from slipping when it is started on a slope.

All wheel drive (AWD)

The all wheel drive function is applied for improving tracking and hauling power, steering capability and stability, and off-road driving power.

Full air braking system and ABS

Applying a full-air braking system to the vehicle for reducing the force required for pressing the pedal, and ensuring precise braging force.

Applying ABS for keeping the braking force and steering capability intact and securing vehiclestability on anuneven surface.

Air pressure control device of tire (optional)

Evacuates from poor subsoil by controlling air pressure of tire inside the cabin

Cabin

This cab-over cabin provides improved legibility compared with bonnet-type. Applying specifications of commercial vehicles enhances convenience of driving vehicle

Air conditioner

Provides a pleasant environment to riders all the time and secures visibility of a driver by defrosting the windshield.

Instruments and switches

Commercial vehicle instruments for improved legibility, and switches ergonomically arranged for enhanced operability

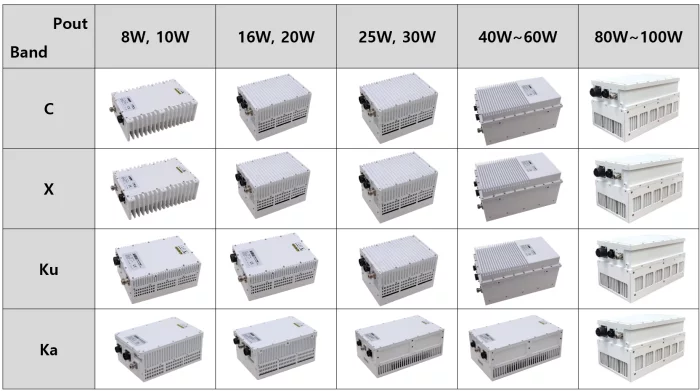

XMW Inc.

SATCOM RF Transmitters/Receivers

A comprehensive line of products in C, X, Ku, Ka and Q-band for SATCOM and 5G&6G are available as off-the-shelf items or custom-made design upon request. These products are specialized in various types of mobility environment including airborne application. We serve the customers in more than 20 countries with fully field proven products.

The new era of wireless communication requires a converged solution of SATCOM and 5G&6G in the aspects of technologies and services. XMW is preparing for the new era with the solutions inherited from SATCOM and 5G&6G business for more than a decade.

Hessed Korea

PICO-DSX ASSAULTER’S PLATE CARRIER

The lightest plate carrier of 1.95 lbs

Taktic buckle system for quick connect & release

Antibacterial/FR treated padded spacer mesh system

Poly mesh cummerbund for increased ventilation

Flush admin chest pocket with internal elastic straps

Rear internal pocket for storage

Elastic webbing straps for cable management

PALS webbing for MOLLE attachment

Removable front flap

Zipper for DS Assaulter's Zip-On Back Panels

QASM buckle System

Plate pocket incorporated 4-way stretch to accommodate multiple plate thickness

Composition

Material : 500D Cordura® + ARAMID / PV®

Size :

Small : 8.5" x 11.5" Plate Pocket

Medium : 9.3" x 12.3" Plate Pocket

Large : 10" x 13" Plate Pocket

XLarge : 10.9" x 13.8" Plate Pocket

Colors:

MC (MultiCam)

BMC (Black MultiCam)

BK (Black)

RG (Ranger Green)

CYT (Coyote Brown)

Digital Directory

Digital Directory