한국어로 페이지 보기

Seoul ADEX 2025 Digital Directory

Plan your trip to Seoul ADEX 2025 using our state of the art Digital Directory

Register in seconds with just your email

Directory Features

To help you at the show

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

Plan your trip

Use the bookmarking and event planning tool to research the companies you would like to visit and the products you are interested in finding. You will be able to locate all of your saved companies on our floorplan

Advanced Search

Utilize our advanced search function to quickly locate products, people, and companies. Our state-of-the-art technology thoroughly scans all exhibitor information, delivering precise and relevant results

Interactive Floorplan

Navigate the show effortlessly with our directory. Use the floorplan to locate companies you want to visit and to find your way to onsite restaurants, toilets and site entrances and exits.

On-platform Messaging

Reach out to exhibitors and visitors directly on our platform to set up meetings, or request more information.

Some of our latest content

Companies, Products, News, Events

Telcom International

Micross

We can manufacture products that comply with MIL-PRF and MIL-STD standards, and offer radiation-hardened designs, hermetic packaging, and Class S and Class K screening services.

Space

Satellite Communication

Providing optimized performance in space radiation environments with radiation-hardened semiconductors and hermetic packaging solutions.

Deep Space & Earth Observation

Ensuring long-term mission reliability with high-reliability power management ICs, RF components, and Class K screening products.

Launch Vehicle Electronics

Providing rugged packaging and hermetic components that withstand extreme temperatures and shocks.

Defense

Missile & Precision Guided Munitions

Ensuring lightweight and shock-resistant performance with miniaturized, high-reliability semiconductors and customized packaging. Electronic Warfare & Radar

Providing high-performance components, including high-frequency RF components, power amplifiers, and high-speed digital ICs.

Avionics & Secure Communications

Providing EMI/EMC-compliant circuit protection devices and highly reliable power management solutions.

EO System

Civilian thermal imaging equipment solution

This equipment is a thermal imaging system that provides an advanced, lightweight solution for nighttime surveillance.

It uses a high-resolution uncooled thermal sensor to detect differences in the thermal signatures of objects across various fields of view.

It can also detect a wide range of targets even under adverse weather conditions such as smoke or fog.

In addition, it is used for civilian security purposes and for detecting abnormalities in facilities using thermal imaging.

Korea Aerospace Industries

CAS500 Compact Advanced Satellite 500 ∙ Phase #1

The CAS-500(Compact Advanced Satellite), phase #1 project is the project in which KAI aims to develop a CAS500-1 by operating a joint design team with Korea Aerospace Research Institute(KARI) and to transfer the government’s satellite development technology to the industries. Then, KAI initiates the development of the CAS500-2 project and establish the industry-led development as well as mass-production infrastructure.

ARS ELECTRONICS S.r.l.

RELAYS

ALTERNATIVES TO: MS25271 / MS25395 / MS25267 / MS25269 / MS25273 / MS27418

View page in English

디렉터리 기능

전시회 도우미

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

방문 계획 수립

북마크 도구와 이벤트 플래너를 사용해 방문하고자 하는 기업과 관심 있는 제품을 검색하세요. 저장한 모든 항목을 조회할 수 있습니다

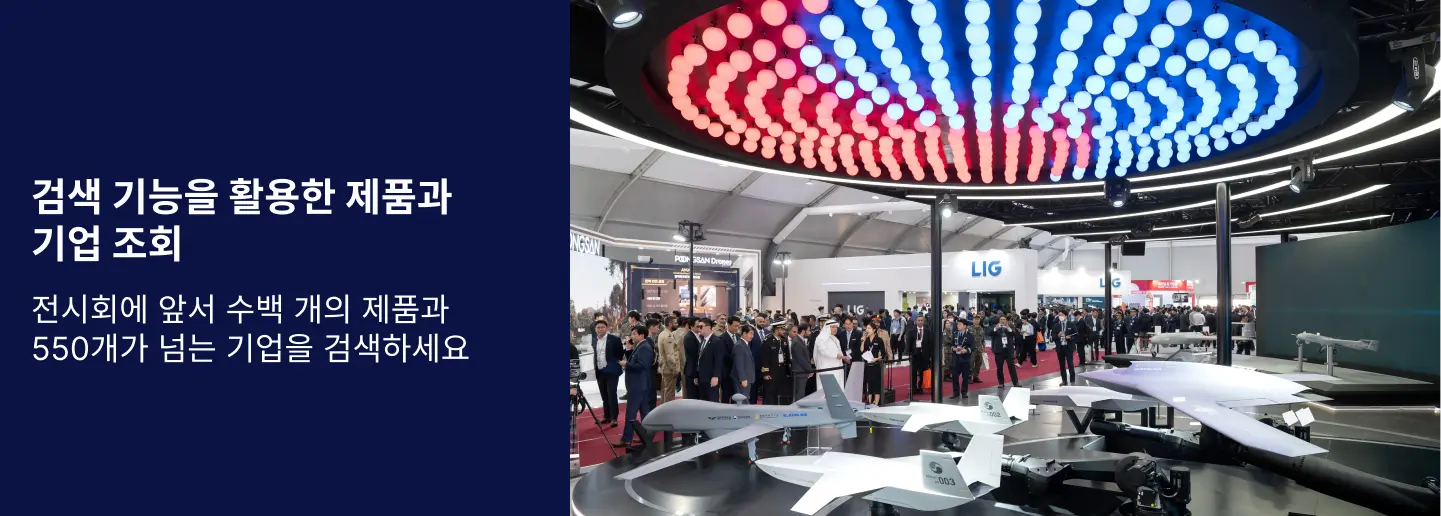

고급 검색

고급 검색 기능을 사용하여 상품, 인물, 기업의 위치를 빠르게 조회할 수 있습니다. 최첨단 기술을 통해 모든 참가사의 정보를 철저히 스캔하여 세밀하고 관련성 있는 정보를 제공합니다

상호작용 가능 평면도

디렉터리를 사용해 전시회를 손쉽게 둘러보세요. 방문하고자 하는 기업의 위치와, 행사장 내 식당, 화장실, 출입구를 평면도에서 찾을 수 있습니다.

플랫폼 내 메시지

플랫폼 상의 전시 참가사와 관람객에게 직접 연락하여 미팅을 신청하거나 추가 정보를 요청하세요.

최신 콘텐츠

기업, 상품, 뉴스, 이벤트

Sangdo Electronics co.,Ltd

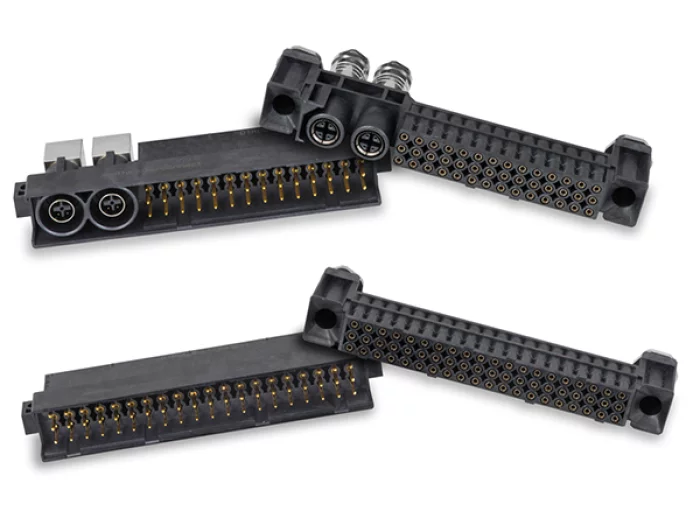

Intercompact Series

Optimized and qualified for next generation Electronic Control Units the Intercompact Series is an innovative solution for PCB to PCB and floating mouting rack and panel applications currently offered in both signal and Ethernet versions. Designed to meet the requirements of the rail and industrial environments, it is also suitable for other demanding markets such as defence, space and test & measurement.

WIREMASTERS

WIRE

A wire in military or aerospace applications is a conductor used to transmit electrical power or signals between components in aircraft, vehicles, or defense systems.

_700.webp)

Arion Communication Co., Ltd.

TYTO 6

The device consists of a power supply, dedicated Iridium and GNSS antenna, BLE, three configurable inputs/outputs, RS232, and CANbus in an environmentally sealed enclosure. Includes an Iridium Short Burst Data (SBD) modem that allows remote devices to send and receive satellite messages from anywhere in the world.

EMCORE

QRS116 Single-Axis Tactical Grade Analog Gyroscope (Non-ITAR)

The QRS116 is a compact angular rate sensor ideally suited for applications in tactical, aerospace and mission-critical instrumentation.

The QRS116 features exceptionally low noise, fast start-up, and a simple electrical interface, the QRS116 has no moving parts ensuring long service life and high MTBF.

System Performance

PARAMETERS SPECIFICATIONS

Standard Ranges ±100°/sec

Input Voltage + 5 Vdc ±5% regulation

Short Term Bias Stability (100 sec at const. temp) 3 deg/hr

Output Noise ( DC to 100 Hz) ≤ 0.002°/√Hz*

* Values Indicated are for ±100°/sec. Range

Features

Exceptional Bias Stability

Unprecedented Low Angle Random Walk Values

Superior Vibration Performance

Compact Industry-Standard Package (Same as QRS11)

Rugged, Compact Package Integrates easily

Applications

Tank Turret Stabilization

Defense Fixed Wing

Defense Helicopter

Unmanned Aerial Vehicles

UGV – Unmanned Ground Vehicle

Platform Stabilization

Camera Stabilization

Antenna Stabilization

ROV – Remotely Operated Vehicle

Digital Directory

Digital Directory