한국어로 페이지 보기

Seoul ADEX 2025 Digital Directory

Plan your trip to Seoul ADEX 2025 using our state of the art Digital Directory

Register in seconds with just your email

Directory Features

To help you at the show

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

Plan your trip

Use the bookmarking and event planning tool to research the companies you would like to visit and the products you are interested in finding. You will be able to locate all of your saved companies on our floorplan

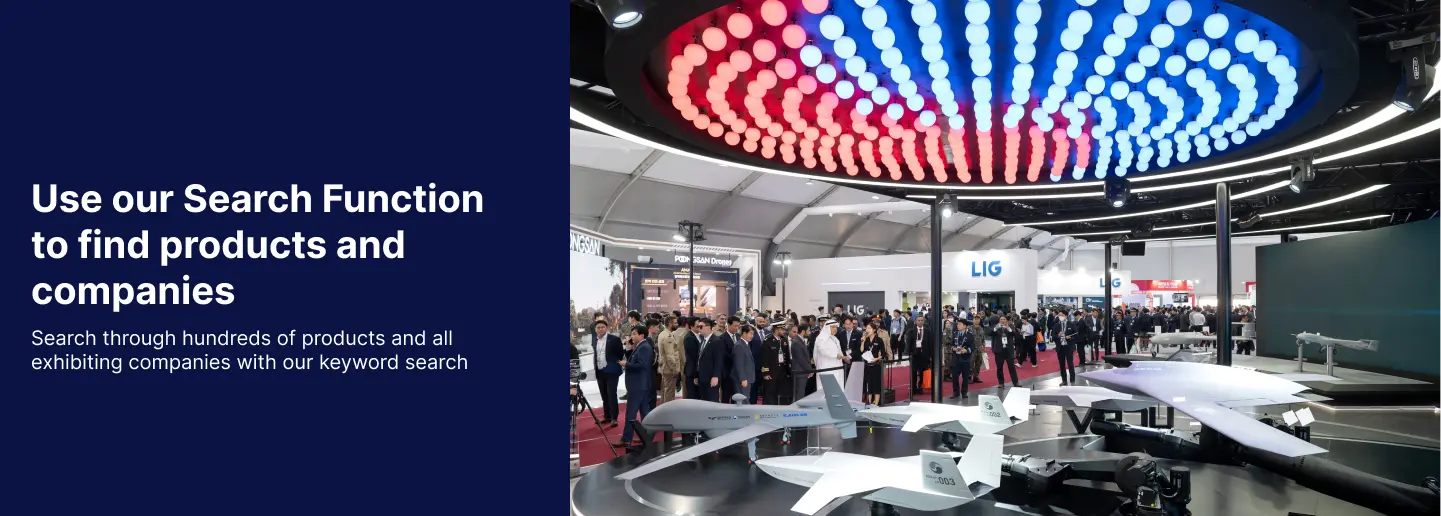

Advanced Search

Utilize our advanced search function to quickly locate products, people, and companies. Our state-of-the-art technology thoroughly scans all exhibitor information, delivering precise and relevant results

Interactive Floorplan

Navigate the show effortlessly with our directory. Use the floorplan to locate companies you want to visit and to find your way to onsite restaurants, toilets and site entrances and exits.

On-platform Messaging

Reach out to exhibitors and visitors directly on our platform to set up meetings, or request more information.

Some of our latest content

Companies, Products, News, Events

DUKSAN AETHERCT Co., Ltd.

IMDG Tube Skids

Toxic gases, such as Silane (SiH4), Nitrogen Trifluoride (NF3), Sulphur Hexafluoride (SF6), Ammonia (NH3), Nitrous Oxide (N2O), etc. must be contained in IMDG certified MEGC tubes for ocean transportation.

For high purity gases such as SiH₄, and NF₃, DS Aether CT provides internal-polished tubes to a grade of 3S, 25S, etc. depending on customer's requirements.

DS Aether CT’s tubes keep moisture levels below 1 ppm or 3 ppm by a heated vacuuming process so that gas quality can be maintained at high purity level.

Jaewon Korea

MIL-DTL-5015

The MIL-DTL-5015 series of connectors were developed as military standard connectors and applied to various military equipment, it is also used in general industries, medical care, electric vehicles, robots and automation facilities based on its high durability and reliability. This series is threaded coupling and the connection between the contact and the wire is based on soldering. It can be used compatibly with third-party products of the same standard since it is produced according to military standards.

Teledyne FLIR LLC

Border Coastal Surveillance Brochure US

Border security and coastal surveillance are 24/7 operations that can’t afford downtime

or periods of reduced readiness. Guarding against illegal immigration, smuggling, and

terrorism demands reliable long-range threat detection and positive identification of

potential threats all day, all night, and in all conditions.

GIFAS

Environment

Confronting climate change, designing quieter and more efficient airplanes, developing innovative satellites to observe the Earth's system: our sector is using its skills to their utmost to take action for the environment. Our two main objectives are to advance our technologies so that we can better observe our planet and to create sustainable air travel.

View page in English

디렉터리 기능

전시회 도우미

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

방문 계획 수립

북마크 도구와 이벤트 플래너를 사용해 방문하고자 하는 기업과 관심 있는 제품을 검색하세요. 저장한 모든 항목을 조회할 수 있습니다

고급 검색

고급 검색 기능을 사용하여 상품, 인물, 기업의 위치를 빠르게 조회할 수 있습니다. 최첨단 기술을 통해 모든 참가사의 정보를 철저히 스캔하여 세밀하고 관련성 있는 정보를 제공합니다

상호작용 가능 평면도

디렉터리를 사용해 전시회를 손쉽게 둘러보세요. 방문하고자 하는 기업의 위치와, 행사장 내 식당, 화장실, 출입구를 평면도에서 찾을 수 있습니다.

플랫폼 내 메시지

플랫폼 상의 전시 참가사와 관람객에게 직접 연락하여 미팅을 신청하거나 추가 정보를 요청하세요.

최신 콘텐츠

기업, 상품, 뉴스, 이벤트

EMCORE

GEO-FOG 3D Dual Inertial Navigation System (INS) (Non-ITAR)

EMCORE’s exclusive photonic integrated chip (PIC) technology delivers improved reliability and repeatability. The precision non-ITAR GEO-FOG 3D Dual features two GNSS antennas on a fixed PTK baseline to offer increased heading, pitch, and roll accuracy for static and dynamic applications where a single antenna system can be problematic. This dual antenna INS is the best choice for systems requiring heading at start-up or in low dynamic conditions.

Highlights

Data rate 10x faster than other available systems

Cutting-edge sensor fusion for dependable, precise navigation in a full array of applications and conditions

Six degrees of freedom (DoF) IMU with integrated gyros and accelerometers

Technology Details

Photonic Integrated Chip Technology

EMCORE’s new photonic integrated chip (PIC) technology reimagines FOG technology by replacing individual fiber components with an innovative integrated planar optic chip. This results in a FOG with PIC Inside™ that’s even more reliable and delivers superior repeatability unit-to-unit. With three of these integrated photonic gyros at its core, the P-1750 IMU enables the GEO-FOG to provide the safe, accurate performance autonomous platforms demand.

Learn More

DSP Technology

EMCORE’s DSP electronics improve FOG performance in critical areas such as scale factor and bias vs. temperature, scale factor linearity, and maximum input rate. EMCORE’s exclusive DSP design overcomes the limitations of analog signal processing, eliminating temperature-sensitive drift and rotation errors.

GEO•FOG Manager

The GEO•FOG Manager is ideal when integrating EMCORE’s GEO•FOG 3D and GEO•FOG 3D Dual INS.

Learn More

Developer’s Kit for Rapid Integration

The KVH FOG/IMU Developer’s Kit includes easy-to-use software to accelerate your IMU and FOG integration, development, and interface efforts.

Illumia Labs Inc

SAF-FIRES

SAF-FIRES™ is a standards-based, image generator agnostic, and scalable Call-For-Fire and Close Air Support training simulation with autonomous Smart Trainer suitable for deployment in Joint Fires and accreditable JTAC training simulators. Built upon the same Call-For-Fire and Close Air Support software engine that powers the accredited simulation Fires FST™, SAF-FIRESTM delivers the same mature and complete Joint Fires training solution but makes it available for integration with any DIS, HLA or CIGI compatible simulation or Image Generator.

Supporting both conventional near-peer and counter-insurgency operational scenarios, SAF-FIRES™ enables JFOs and JTACs to train realistically in a modern complex battlespace against an agile and adaptive adversary. Heightened realism and cognitively challenging training are enabled through the incorporation of non-combatants, urban clutter, UAV surveillance, various close air support platforms and accurate military targeting procedures.

SU Optics

ACTUS® CORE-5 Dot Sight

The ACTUS® CORE-5 is the latest development of our Dot Sight lineup. It delivers the same high-end optical performance and legendary durability as our existing CORE Dot Sights, now with enhanced features based on feedback from professional users.

The ACTUS® CORE-5 offers three reticle designs and improved ergonomics, with relocated illumination controls on the top for ambidextrous operation—ensuring seamless adjustments while staying clear of chest rigs and plate carriers when slung.

A dedicated night vision override switch allows for instant adaptation to sudden lighting changes, while the CR2032 battery provides an impressive 20,000-hour runtime at Level 8 brightness.

_700.webp)

TelePIX Co., Ltd.

Chouette

A Very High Resolution (0.75 m GSD) and Wide-Field of View (24 km swath) optical payload under development. Designed for microsatellite integration, Chouette combines sub-meter detail with wide-area coverage, a unique balance that expands the scope of commercial EO applications beyond what current systems offer.

Digital Directory

Digital Directory