한국어로 페이지 보기

Seoul ADEX 2025 Digital Directory

Plan your trip to Seoul ADEX 2025 using our state of the art Digital Directory

Register in seconds with just your email

Directory Features

To help you at the show

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

Plan your trip

Use the bookmarking and event planning tool to research the companies you would like to visit and the products you are interested in finding. You will be able to locate all of your saved companies on our floorplan

Advanced Search

Utilize our advanced search function to quickly locate products, people, and companies. Our state-of-the-art technology thoroughly scans all exhibitor information, delivering precise and relevant results

Interactive Floorplan

Navigate the show effortlessly with our directory. Use the floorplan to locate companies you want to visit and to find your way to onsite restaurants, toilets and site entrances and exits.

On-platform Messaging

Reach out to exhibitors and visitors directly on our platform to set up meetings, or request more information.

Some of our latest content

Companies, Products, News, Events

REDCOM Laboratories, Inc.

REDCOM Secure Voice Gateway Type-1 NSA ACC-Compliant Gateway Using the GD Sectéra® Viper™ Secure Phone

A REDCOM SVG system consists of one or more REDCOM Sigma® SVG-1200 units and a series of standard production General Dynamics Sectéra vIPer phones. Each REDCOM SVG-1200 can interface with up to 12 vIPer phones, which act as voice encryptors for TDM or VoIP voice networks. The encryptors allow any line, trunk, or conference port to conduct secure voice communications with any SCIP-capable device. If more than 12 secure talk paths are required, multiple SVG-1200 units may be networked together.

HANMI HYDRAULIC MACHINERY CO., LTD.

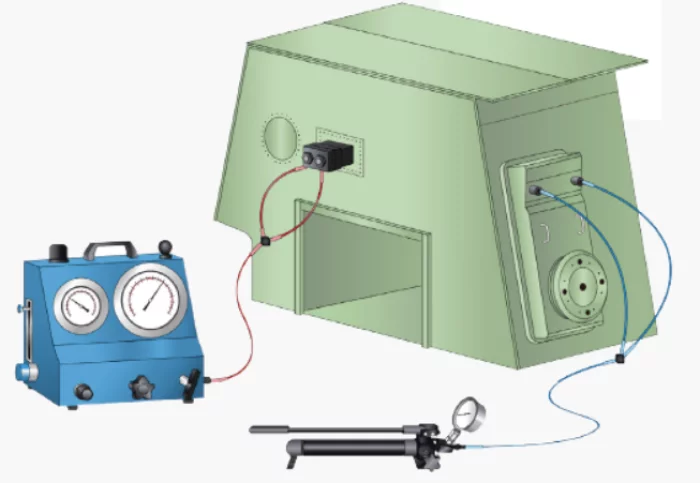

Main engine hydraulic tools package(Pump, Jack, Hose, Coupler)

This hydraulic tool package product is an ultra-high-pressure tool product used to assemble and disassemble major parts that make up the engine, and has been supplied to domestic and overseas engine customers since our foundation. The composition consists of a hydraulic pump, a hydraulic jack, a hydraulic hose, and a coupler, and supplies one package per ship. The product model can be selected according to the required pressure for each engine type and model.

HANMI HYDRAULIC MACHINERY CO., LTD.

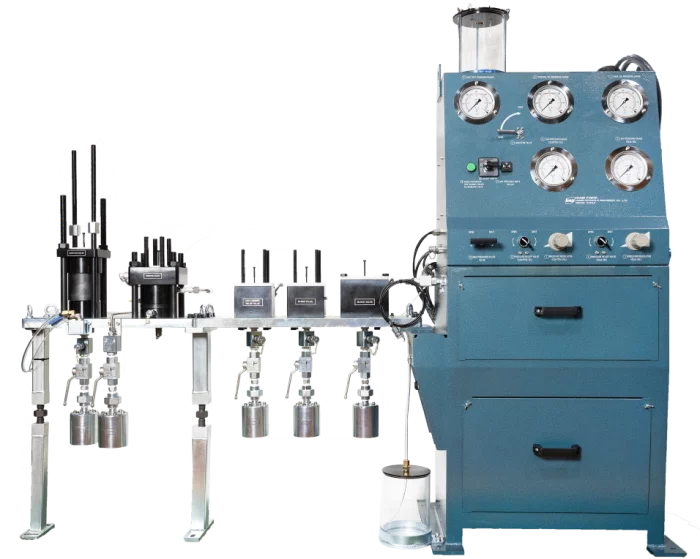

Fuel Valve Test Device

This product is a test-rig to test the injection and function of various fuel (diesel oil, gas) objects of the main engine. This product model is made from slide fuel valve types of traditional diesel engines to latest dual fuel gas engines GI, GI, LGIP, LGIM/X-DFM, and ammonia fuel valve engines LGIA and X-DFA types, and we are directly doing everything from design to production.

In accordance with the maintenance regulations recommended by Everllence and WIN GD, it is a product that tests the normal functionality of fuel injectors of main engine after disassembling, cleaning and reassembling of fuel injection valves.

Hankuk Carbon

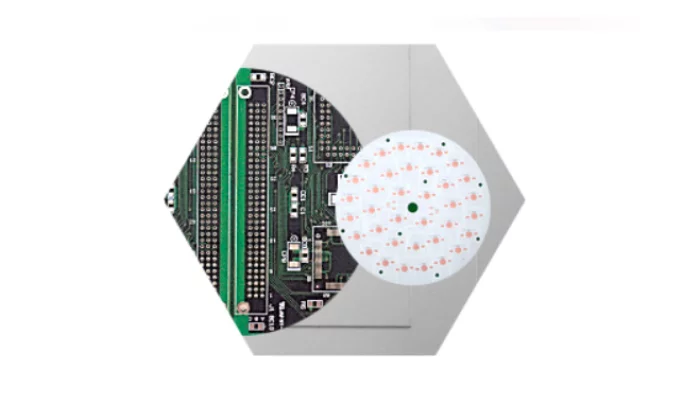

Electronics

Our electronics business sector has been producing copper cladded laminates of printed circuit boards for over 20 years. To meet high heat dissipation for the newest electronic technology, we have developed metal based laminates and carbon laminates.

View page in English

디렉터리 기능

전시회 도우미

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

방문 계획 수립

북마크 도구와 이벤트 플래너를 사용해 방문하고자 하는 기업과 관심 있는 제품을 검색하세요. 저장한 모든 항목을 조회할 수 있습니다

고급 검색

고급 검색 기능을 사용하여 상품, 인물, 기업의 위치를 빠르게 조회할 수 있습니다. 최첨단 기술을 통해 모든 참가사의 정보를 철저히 스캔하여 세밀하고 관련성 있는 정보를 제공합니다

상호작용 가능 평면도

디렉터리를 사용해 전시회를 손쉽게 둘러보세요. 방문하고자 하는 기업의 위치와, 행사장 내 식당, 화장실, 출입구를 평면도에서 찾을 수 있습니다.

플랫폼 내 메시지

플랫폼 상의 전시 참가사와 관람객에게 직접 연락하여 미팅을 신청하거나 추가 정보를 요청하세요.

최신 콘텐츠

기업, 상품, 뉴스, 이벤트

_700.webp)

ICEYE

SAR Data

Only SAR (synthetic aperture radar) satellites can collect images day and night and in any weather. Only ICEYE’s constellation of small and agile SAR satellites is able to revisit the same location in space daily and even sub-daily, enabling a level of change detection that’s never been possible before.

Honeywell International

5 Ways This Cockpit Update Will Change Flight As We Know It

Then:Using traditional dashboard displays and complex maps during simulations or flights can be complicated for pilots-in-training. Soon:Equipped with the clearest symbology yet and track-based Synthetic Vision System (SVS) to give pilots an easy-to-understand view of their flight and route, Honeywell Anthem is designed to help every pilot feel comfortable in the cockpit.

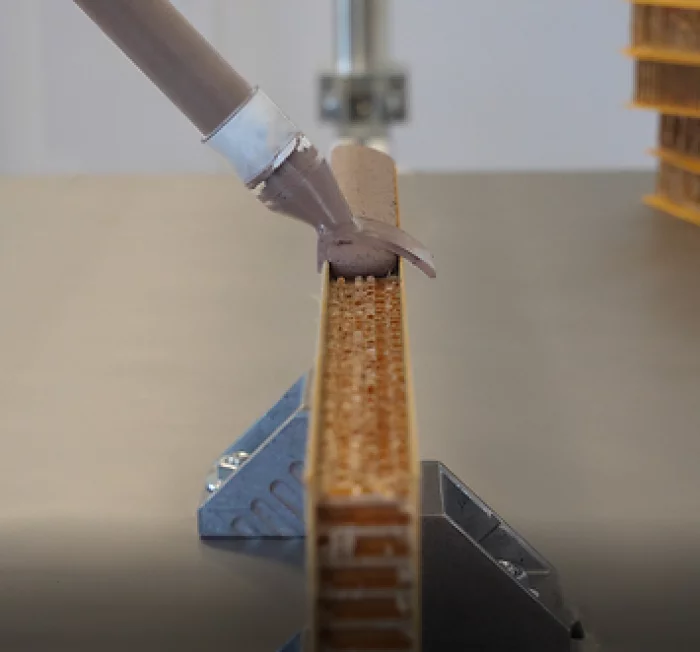

ViscoTec Pumpen- u. Dosiertechnik GmbH

Edge Filling – Dosing of Edge Fillers

In addition to honeycomb potting, sandwich components often also have to be sealed and thus reinforced in the edge areas. For this purpose, similar or even identical filling materials are used as those used for filling the honeycombs themselves. Namely, core and edge filling compounds with very low density, which is achieved by enriching the material with hollow spheres.

With our dosing technology, this process can also be automated. The 1-component or 2-component materials are processed gently – without changing their material properties. The material application can be fully automated or semi-automated. Thanks to pulsation-free dispensing, the best results can be achieved with the minimum of effort. This allows you to reduce production times while optimizing production processes at the same time.

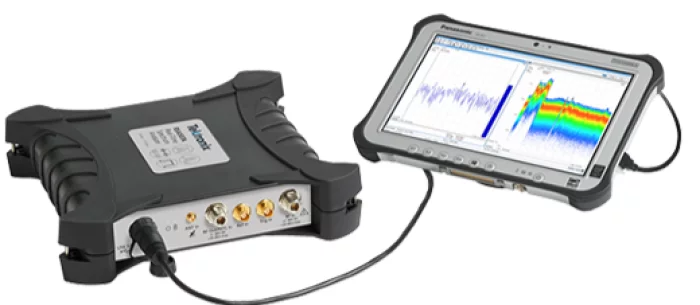

GnK Solution

RSA507A

Portable Real time USB signal analyzer, 9 kHz-7.5 GHz

Digital Directory

Digital Directory