한국어로 페이지 보기

Seoul ADEX 2025 Digital Directory

Plan your trip to Seoul ADEX 2025 using our state of the art Digital Directory

Register in seconds with just your email

Directory Features

To help you at the show

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

Plan your trip

Use the bookmarking and event planning tool to research the companies you would like to visit and the products you are interested in finding. You will be able to locate all of your saved companies on our floorplan

Advanced Search

Utilize our advanced search function to quickly locate products, people, and companies. Our state-of-the-art technology thoroughly scans all exhibitor information, delivering precise and relevant results

Interactive Floorplan

Navigate the show effortlessly with our directory. Use the floorplan to locate companies you want to visit and to find your way to onsite restaurants, toilets and site entrances and exits.

On-platform Messaging

Reach out to exhibitors and visitors directly on our platform to set up meetings, or request more information.

Some of our latest content

Companies, Products, News, Events

.jpg)

Haynes International

Alloy Portfolio

Our broad alloy portfolio enables customers to achieve higher efficiencies, reduce pollution levels, extend product life, and reduce costs. Our corrosion-resistant alloys are generally distinguished by the HASTELLOY® brand and our high-temperature family of alloys are generally distinguished by the brand.

_700.webp)

Green Optics Co., Ltd.

ZnS Matetial

Green Optics possess proprietary CVD-based Zinc Sulfide (ZnS) production technology for defense and industrial multi-wavelength optical materials. We have core technological capabilities to manufacture high-quality ZnS products tailored to meet diverse customer requirements.

ZnS Material Optical Performance and Processing

ZnS materials produced through CVD processes provide high transmittance exceeding 70% in the SWIR wavelength range (8-12 μm). When these materials undergo additional Hot Isostatic Pressing (HIP) treatment, the crystal structure undergoes recrystallization, improving transmission characteristics to achieve over 70% transmittance in the visible (VIS) wavelength range of 0.45-0.8 μm. This process extends the application range of optical materials previously limited to SWIR and LWIR bands, delivering superior optical performance across multi-wavelength regions from VIS to LWIR.

Material Specifications:

- STD-ZnS (Standard ZnS Material): Manufactured via CVD process, exhibits transmittance exceeding 70% in LWIR wavelengths (8-12 μm) with high physical hardness (Knoop hardness: 210 kgf/mm²).

- MS-ZnS (Multispectral ZnS): Converted from STD-ZnS through HIP processing, extends wavelength range into the visible spectrum. While crystal structure recrystallization during this process reduces hardness somewhat (approximately 150 kgf/mm²), it still meets MIL specifications.

This dual-processing approach enables comprehensive wavelength coverage while maintaining military-grade durability standards.

_700.webp)

X-BEAM TECH

Expanded Beam Connector HXB Series

The X-BEAM TECH HXB Connectors, featuring expanded beam technology, hermaphroditic connection, rugged construction for field deployment have been designed for harsh environment applications such as military tactical communications, avionics, offshore systems, outside broadcast, mining and plant.

The expanded beam technology uses expanded and collimated beams to couple optical fibers without any contact. It could allow for optics to be used in areas that have been quite restrictive due to presence of damage or contamination at the fiber end. Hermaphroditic connector design enables fast deployment by daisy-chaining multiple cable segments. HXB series connectors also enable transfer of electrical signal or power using hybrid insert configuration.

Hessed Korea

PICO-MVW-DSX ASSAULTER’S PLATE CARRIER

Taktic buckle system for quick connect & release

Antibacterial/FR treated padded spacer mesh system

Poly mesh cummerbund for increased ventilation

XFrame® Dynamic Load Carrige® compatible

Compatible with our entire accessories line

Flush admin chest pocket with internal elastic straps

PALS webbing for MOLLE attachment

Zipper for DS Assaulter's Zip-On Back Panels

QASM buckle system

Increased structural integrity and reduced rear deformation

Internal plate pocket retention straps accommodate several different plate thickness

Soft armor included

Composition

Material: 500D Cordura® + ARAMID/PV®

Size :

Small / Medium : 8.5" x 11.5” -9.3" x 12.3" Plate Pocket

Front Panel Area of Coverage : Length 13.25” Width 11"

Large / XLarge : 10" x 13"- 10.9" x 13.8” Plate Pocket

Front Panel Area of Coverage : Length 15" Width 12"

Colors:

MC (MultiCam)

BMC (Black MultiCam)

BK (Black)

RG (Ranger Green)

CYT (Coyote Brown)

View page in English

디렉터리 기능

전시회 도우미

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

방문 계획 수립

북마크 도구와 이벤트 플래너를 사용해 방문하고자 하는 기업과 관심 있는 제품을 검색하세요. 저장한 모든 항목을 조회할 수 있습니다

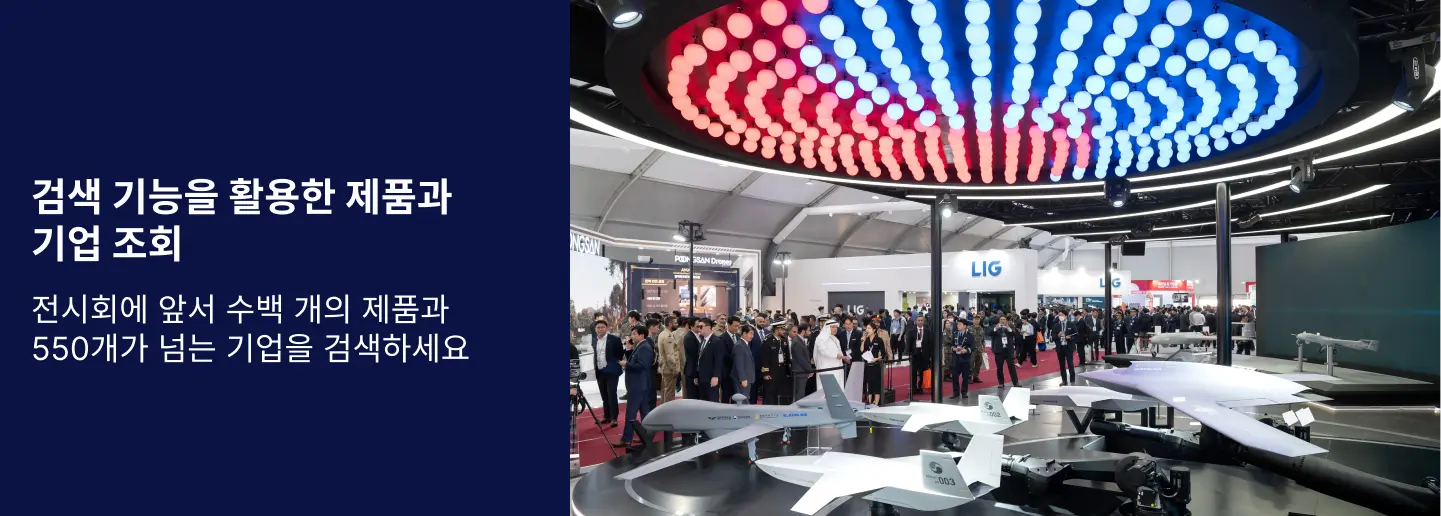

고급 검색

고급 검색 기능을 사용하여 상품, 인물, 기업의 위치를 빠르게 조회할 수 있습니다. 최첨단 기술을 통해 모든 참가사의 정보를 철저히 스캔하여 세밀하고 관련성 있는 정보를 제공합니다

상호작용 가능 평면도

디렉터리를 사용해 전시회를 손쉽게 둘러보세요. 방문하고자 하는 기업의 위치와, 행사장 내 식당, 화장실, 출입구를 평면도에서 찾을 수 있습니다.

플랫폼 내 메시지

플랫폼 상의 전시 참가사와 관람객에게 직접 연락하여 미팅을 신청하거나 추가 정보를 요청하세요.

최신 콘텐츠

기업, 상품, 뉴스, 이벤트

SU Optics

ACTUS® ARKS4325 Long Range Riflescope

The ACTUS® ARKS4325 (4-32X, 56mm FFP) Long Range Riflescope is built for precision and durability, designed to meet the needs of professional users in diverse environments.

Featuring a First Focal Plane (FFP) optical design, it ensures fast and accurate target coverage across all magnification levels. The illuminated reticle provides clear and smooth targeting, even in low-light conditions like dawn or dusk.

Whether in demanding or dynamic environments, the ACTUS® ARKS4325 delivers outstanding performance, making it the ideal riflescope for users who require unmatched reliability and accuracy in critical moments.

ZYX Technology

WORKS

WORKS is a powerful CAD utility suite developed by ZYX Technology, designed to enhance drafting productivity through automation and specialized tools. It includes over 450 features tailored for civil engineering, architecture, and general 2D drafting work.

A key advantage of WORKS is its dual compatibility—it works seamlessly with both ZYXCAD PRO and AutoCAD Full versions, making it an excellent solution for organizations using diverse CAD environments.

WORKS automates repetitive drafting tasks such as block insertion, layer control, dimensioning, annotation, and bulk editing. For civil engineering workflows, it offers advanced tools like terrain cross-sections, longitudinal profile creation, drainage design, and grading support.

In architectural drafting, WORKS streamlines operations like door/window placement, wall dimensioning, floor labeling, and symbol standardization. These features reduce manual errors and improve consistency and output quality.

Its smart batch-editing functions and preconfigured settings allow users to apply company CAD standards easily, reducing project setup time and improving team collaboration. All tools are organized in an intuitive ribbon interface, allowing both beginners and experts to maximize productivity.

By minimizing repetitive work and standardizing key processes, WORKS dramatically improves drawing efficiency and accuracy. It is trusted by government agencies, educational institutions, and enterprises for large-scale design projects across Korea and beyond.

Whether you're creating road plans, site layouts, floor plans, or technical diagrams, WORKS simplifies complex workflows and saves time without compromising quality.

_700.webp)

AeroMaster Corporation (AMC)

ECMU

Monitors abnormal engine operation based on digital and analog signals from the aircraft engine.

It calculates engine life indices and detects engine malfunctions for generate a Pilot Fault List (PFL), which will stored in memory.

When an engine failure is detected, it provides warning for display on the Central Maintenance Panel (CMP).

Developed as a replacement for obsolete, achieving 60% cost competitiveness compared to equivalent products.

- x1 MIL-STD-1553B

- x16 Discrete Inout

- x14 Discrete Output

- x3 Analog Input

- x1 RS-232

- Size: 283 x 265 x 89 (mm)

- Weight : 4.1Kg

- Environment : MIL-STD-810G

- EMI/EMC : MIL-STD-461G

- Power : MIL-STD-704F (28VDC, 25W)

_700.webp)

Mutronics, Inc.

Multi-Function Radar Antenna, Radome

Phased Array Multi Function Antenna including Radome

Digital Directory

Digital Directory