한국어로 페이지 보기

Seoul ADEX 2025 Digital Directory

Plan your trip to Seoul ADEX 2025 using our state of the art Digital Directory

Register in seconds with just your email

Directory Features

To help you at the show

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

Plan your trip

Use the bookmarking and event planning tool to research the companies you would like to visit and the products you are interested in finding. You will be able to locate all of your saved companies on our floorplan

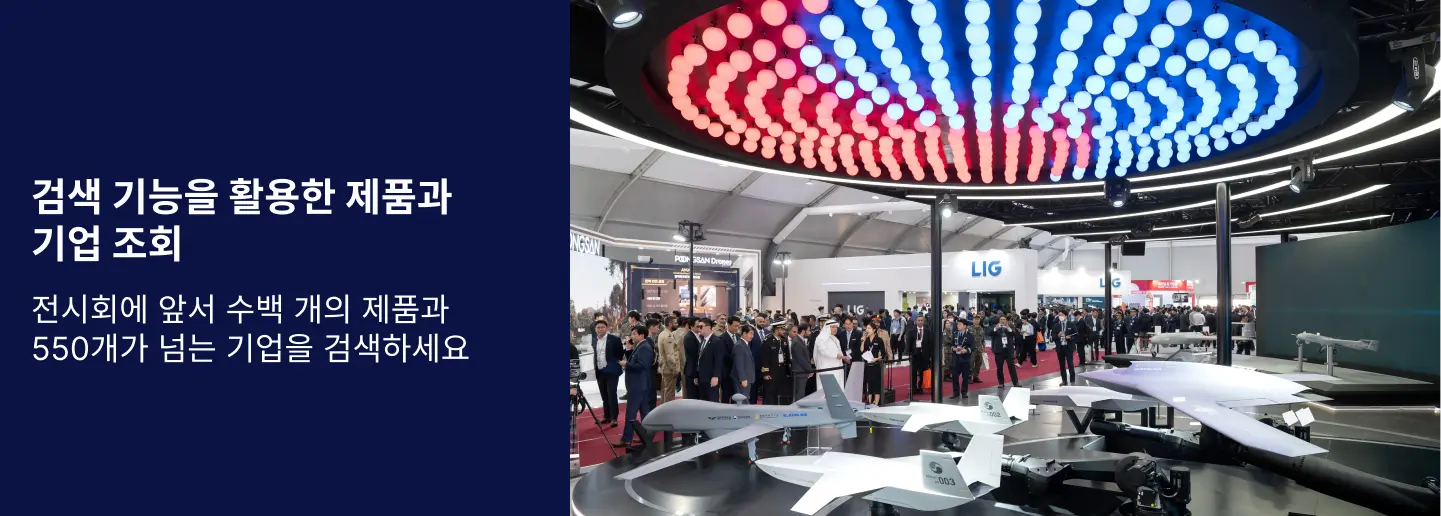

Advanced Search

Utilize our advanced search function to quickly locate products, people, and companies. Our state-of-the-art technology thoroughly scans all exhibitor information, delivering precise and relevant results

Interactive Floorplan

Navigate the show effortlessly with our directory. Use the floorplan to locate companies you want to visit and to find your way to onsite restaurants, toilets and site entrances and exits.

On-platform Messaging

Reach out to exhibitors and visitors directly on our platform to set up meetings, or request more information.

Some of our latest content

Companies, Products, News, Events

Korea Defense Industry (KD Ind.)

IPS development

Development of an integrated support system for total life cycle management of weapon systems

.jpg)

Jonal Laboratories

High Temperature & Flame Resistant Aerospace Seals

Jonal Labs specializes in high temperature and flame resistant aerospace seals from design assistance to final product and maintenance.

Hydraulics International Inc.

Hydraulics International, Inc. At A Glance

Hydraulics International, Inc. (HII), headquartered in Chatsworth, California, U.S.A., is a leading worldwide supplier of integrated products, services and support to military forces, aviation and commercial industries, Government agencies and prime contractors. Focused on defense and commercial technology, the Company develops, manufactures and supports a broad range of systems for over one hundred industries as well as mission-critical and military sustainment requirements over the globe. Our extensive design capabilities enable us to produce the most sophisticated technological units known in the Aircraft Ground Support Equipment (AGSE) profession.

HII has been recognized as one of the largest defense ground support equipment technology companies in the world. We hold leading market positions in ammunition loading systems, aircraft hydraulic system testing, aircraft cabin pressure testing, power systems, environmental control systems, military trailers, high-pressure gas and liquid systems, flow measuring equipment, and integrated logistics and support services.

Our corporate, engineering and manufacturing facilities, located in Chatsworth, CA and Forsyth, GA, encompass over 625,000 sq. feet of production space. Our manufacturing facility is equipped with state-of-the-art equipment such as CNC lathes and mills, computerized tube bending, full sheet laser and waterjet, automatic press brake and programmable punch press, laser topography scanners, and other quality verification devices.

HII has been recognized as one of the largest defense ground support equipment technology companies in the world. We hold leading market positions in ammunition loading systems, aircraft hydraulic system testing, aircraft cabin pressure testing, power systems, environmental control systems, military trailers, high-pressure gas and liquid systems, flow measuring equipment, and integrated logistics and support services.

Our corporate, engineering and manufacturing facilities, located in Chatsworth, CA and Forsyth, GA, encompass over 625,000 sq. feet of production space. Our manufacturing facility is equipped with state-of-the-art equipment such as CNC lathes and mills, computerized tube bending, full sheet laser and waterjet, automatic press brake and programmable punch press, laser topography scanners, and other quality verification devices.

CBOL Corporation

AuraGen Underhood Power Generator

AuraGen® ... Unlike a traditional generator, this induction power system fits under the hood of a vehicle and can generate enough pure sine wave electricity to handle your power needs.

The AuraGen's safety, reliability, portability, virtually silent operation, and convenience make it ideal for use during everyday commercial work or anywhere that conventional power is absent. No maintenance, no theft problems and no hazard for employees means higher productivity and higher profits.

The AuraGen® comes complete with the AuraGen® power source, electronics, idle control, and mounting bracket and provides an environmentally friendly alternative to heavy polluting gensets. AuraGen® is available for most fleets, municipal and work site vehicles as well as full-sized pickups and SUV's.

View page in English

디렉터리 기능

전시회 도우미

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

방문 계획 수립

북마크 도구와 이벤트 플래너를 사용해 방문하고자 하는 기업과 관심 있는 제품을 검색하세요. 저장한 모든 항목을 조회할 수 있습니다

고급 검색

고급 검색 기능을 사용하여 상품, 인물, 기업의 위치를 빠르게 조회할 수 있습니다. 최첨단 기술을 통해 모든 참가사의 정보를 철저히 스캔하여 세밀하고 관련성 있는 정보를 제공합니다

상호작용 가능 평면도

디렉터리를 사용해 전시회를 손쉽게 둘러보세요. 방문하고자 하는 기업의 위치와, 행사장 내 식당, 화장실, 출입구를 평면도에서 찾을 수 있습니다.

플랫폼 내 메시지

플랫폼 상의 전시 참가사와 관람객에게 직접 연락하여 미팅을 신청하거나 추가 정보를 요청하세요.

최신 콘텐츠

기업, 상품, 뉴스, 이벤트

Hankuk Carbon

Glass Papers

GP division is producing Glass paper in the wet by glass fiber fabric as a main ingredient.

Glass Paper has a dimensional stability, heat resistance, chemical resistance, electrical insulation, Print Processability, heat insultion and so on. Due to its advanced quality, the Glass Paper is used by many manufacturers globally for floorings, buildings, exterior electronics.

Also, it is used for inorganic filter products, and diverse parts are under researching as its demands rise up.

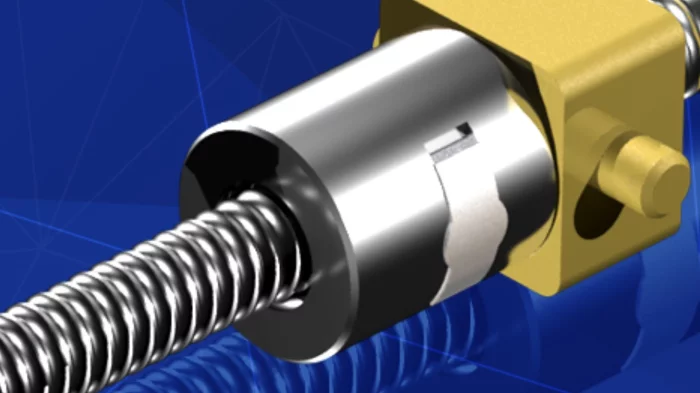

KIM Co., Ltd.

Ball Screw

The main function of the ball screw is to convert the rotational motion of the actuator to linear and it boasts a small precision and high strength. also implements a precision driving with minimal backlash.

GIFAS

Témoignage d'Elixir Aircraft, adhérent au GIFAS

Suite au Conseil du 7 octobre 2021, le GIFAS a accueilli Elixir Aircraft. Découvrez le témoignage de son Président. " Elixir Aircraft, entreprise rochelaise de 60 salariés, a été créé en 2015 afin de répondre aux enjeux de l'aviation légère : réaliser des appareils plus sûrs, plus économes et plus polyvalents .

SU Optics

ACTUS® PARA-3M Magnifier

The ACTUS® PARA-3M is a mission-critical magnifier designed for rapid and precise targeting of close- to mid-range threats in high-intensity operational environments.

With a 3x magnification, it enhances accuracy and adaptability, ensuring superior performance in dynamic combat situations and supporting both near and long-range precision shooting for mission success.

Digital Directory

Digital Directory