한국어로 페이지 보기

Seoul ADEX 2025 Digital Directory

Plan your trip to Seoul ADEX 2025 using our state of the art Digital Directory

Register in seconds with just your email

Directory Features

To help you at the show

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

Plan your trip

Use the bookmarking and event planning tool to research the companies you would like to visit and the products you are interested in finding. You will be able to locate all of your saved companies on our floorplan

Advanced Search

Utilize our advanced search function to quickly locate products, people, and companies. Our state-of-the-art technology thoroughly scans all exhibitor information, delivering precise and relevant results

Interactive Floorplan

Navigate the show effortlessly with our directory. Use the floorplan to locate companies you want to visit and to find your way to onsite restaurants, toilets and site entrances and exits.

On-platform Messaging

Reach out to exhibitors and visitors directly on our platform to set up meetings, or request more information.

Some of our latest content

Companies, Products, News, Events

KUKDONG Telecommunication Co.,Ltd.

Communication Antenna

Communication Antenna for Data and Voice Transmission

BIBUS METALS KOREA

Welding Products

1. Filler Metal

Name Material/Alloy AWS W-No. ISO-No.

Nickel 61 Ni A5.14 ERNi-1 2.4155 SiNi2061

MONEL® 60 Ni-Cu A5.14 ERNiCu-7 2.4377 SNi4060

MONEL® 67 Cu-Ni A5.7 ERCuNi 2.8037 SCu7158

INCONEL® 72 Ni-Cr A5.14 ERNiCr-4 SNi6071

NC 80/20 Ni-Cr 2.4639

INCONEL® 82 Ni-Cr A5.14 ERNiCr-3 2.4806 SNi6082

INCONEL® 622 Ni-Cr-Mo A5.14 ERNiCrMo-10 SNi6022

INCONEL® 625 Ni-Cr-Mo A5.14 ERNiCrMo-3 2.4831 SNi6625

INCO-WELD® 686-CPT Ni-Cr-Mo A5.14 ERNiCrMo-14 SNi6686

INCO-WELD® 725NDUR Ni-Cr-Mo A5.14 ERNiCrMo-15 SNi7725

INCO-WELD® C-276 Ni-Cr-Mo A5.14 ERNiCrMo-4 2.4886 SNi6276

INCONEL® 52 Ni-Cr-Fe A5.14 ERNiCrFe-7 SNi6052

INCONEL® 52M Ni-Cr-Fe A5.14 ERNiCrFe-7A

INCONEL® 92 Ni-Cr-Fe A5.14 ERNiCrFe-6 SNi7092

INCONEL® 617 Ni-Cr-Co-Mo A5.14 ERNiCrCoMo-1 2.4627 SNi6617

NILO® CF36 Ni-Fe

INCOLOY® 65 Ni-Fe-Cr A5.14 ERNiFeCr-1 SNi8065

INCONEL® 718 Ni-Fe-Cr A5.14 ERNiFeCr-2 2.4667 SNi7718

Titanium Grade 1 Ti A5.16-90 ERTi-1

Titanium Grade 2 Ti A5.16-90 ERTi-2

Titanium Grade 5 Ti-Al-V A5.16-90 ERTi-5

Titanium Grade 7 Ti-Pd A5.16-90 ERTi-7

2. Electrodes

Name Material/Alloy AWS W-No. ISO-No.

Nickel 141 Ni A5.11 ENi-1 2.4156 ENi2061

MONEL® 190 Ni-Cu A5.11 ENiCu-7 2.4366 ENi4060

MONEL® 187 Cu-Ni A5.6 ECuNi 2.0838 ECu7158

INCO-WELD® A Ni-Cr-Fe A5.11 ENiCrFe-2 2.4805 ENi6092

INCONEL® 152 Ni-Cr-Fe A5.11 ENiCrFe-7 ENi6152

INCONEL® 182 Ni-Cr-Fe A5.11 ENiCrFe-3 2.4807 ENi6182

INCONEL® 112 Ni-Cr-Mo A5.11 ENiCrMo-3 2.4621 ENi6625

INCONEL® 122 Ni-Cr-Mo A5.11 ENiCrMo-10 ENi6022

INCO-WELD® C-276 Ni-Cr-Mo A5.11 ERNiCrMo-4 2.4887 ENi6276

INCO-WELD® 686CPT Ni-Cr-Mo A5.11 ERNiCrMo-14 ENi6686

INCONEL® 117 Ni-Cr-Co-Mo A5.11 ERNiCrCoMo-1 2.4628 ENi6617

PARTNERS LAB Co., LTD.

Rocket nozzle with conformal cooling channels and isogrid ribbing

This rocket nozzle featuring conformal cooling channels and isogrid ribbing was manufactured using EOS Copper CuCP, a pure copper material optimized for additive manufacturing. The production required approximately 72 hours, taking advantage of the exceptional thermal and electrical conductivity of pure copper to meet demanding aerospace performance requirements.

As one of the few companies in Korea capable of performing metal additive manufacturing with pure copper, we provide advanced technical expertise and support OEM production as well as collaborative technology development projects with various industrial partners.

The showcased component was designed by nTopology and demonstrates the synergy of advanced design optimization with state-of-the-art copper additive manufacturing.

Hydraulics International Inc.

Commercial Aircraft Ground Support Equipment

A world well know Aviation Ground Support Equipment (AGSE) in support of military and commercial aircraft

View page in English

디렉터리 기능

전시회 도우미

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

방문 계획 수립

북마크 도구와 이벤트 플래너를 사용해 방문하고자 하는 기업과 관심 있는 제품을 검색하세요. 저장한 모든 항목을 조회할 수 있습니다

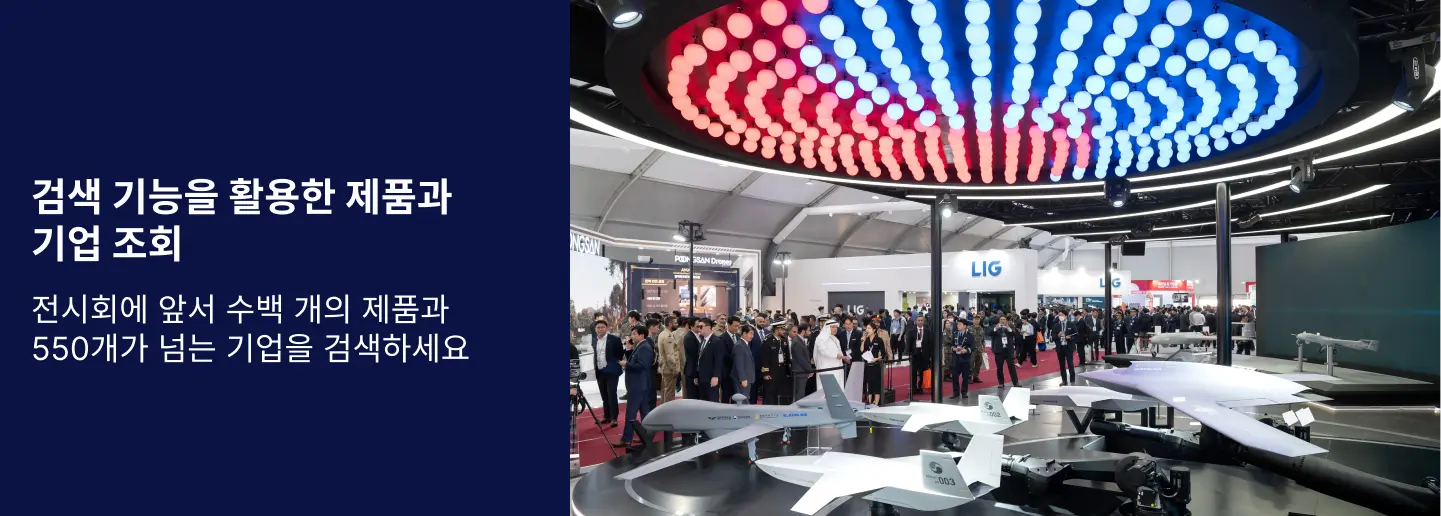

고급 검색

고급 검색 기능을 사용하여 상품, 인물, 기업의 위치를 빠르게 조회할 수 있습니다. 최첨단 기술을 통해 모든 참가사의 정보를 철저히 스캔하여 세밀하고 관련성 있는 정보를 제공합니다

상호작용 가능 평면도

디렉터리를 사용해 전시회를 손쉽게 둘러보세요. 방문하고자 하는 기업의 위치와, 행사장 내 식당, 화장실, 출입구를 평면도에서 찾을 수 있습니다.

플랫폼 내 메시지

플랫폼 상의 전시 참가사와 관람객에게 직접 연락하여 미팅을 신청하거나 추가 정보를 요청하세요.

최신 콘텐츠

기업, 상품, 뉴스, 이벤트

PEI-Genesis

LEMO T-Series Connectors

LEMO T-Series watertight connectors offer durable construction in a package specifically designed for outdoor applications. Learn more: https://www.peigenesi...

_700.webp)

ICEYE

SAR Data

Only SAR (synthetic aperture radar) satellites can collect images day and night and in any weather. Only ICEYE’s constellation of small and agile SAR satellites is able to revisit the same location in space daily and even sub-daily, enabling a level of change detection that’s never been possible before.

SeA Electronics Co., Ltd.

Wire Harness

This product is designed and manufactured to meet customer needs, including power and signal transmission for all weapon systems in the Korean military's land, sea, and air sectors.

SU Optics

ACTUS® ARKS4325 Long Range Riflescope

The ACTUS® ARKS4325 (4-32X, 56mm FFP) Long Range Riflescope is built for precision and durability, designed to meet the needs of professional users in diverse environments.

Featuring a First Focal Plane (FFP) optical design, it ensures fast and accurate target coverage across all magnification levels. The illuminated reticle provides clear and smooth targeting, even in low-light conditions like dawn or dusk.

Whether in demanding or dynamic environments, the ACTUS® ARKS4325 delivers outstanding performance, making it the ideal riflescope for users who require unmatched reliability and accuracy in critical moments.

Digital Directory

Digital Directory