한국어로 페이지 보기

Seoul ADEX 2025 Digital Directory

Plan your trip to Seoul ADEX 2025 using our state of the art Digital Directory

Register in seconds with just your email

Directory Features

To help you at the show

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

Plan your trip

Use the bookmarking and event planning tool to research the companies you would like to visit and the products you are interested in finding. You will be able to locate all of your saved companies on our floorplan

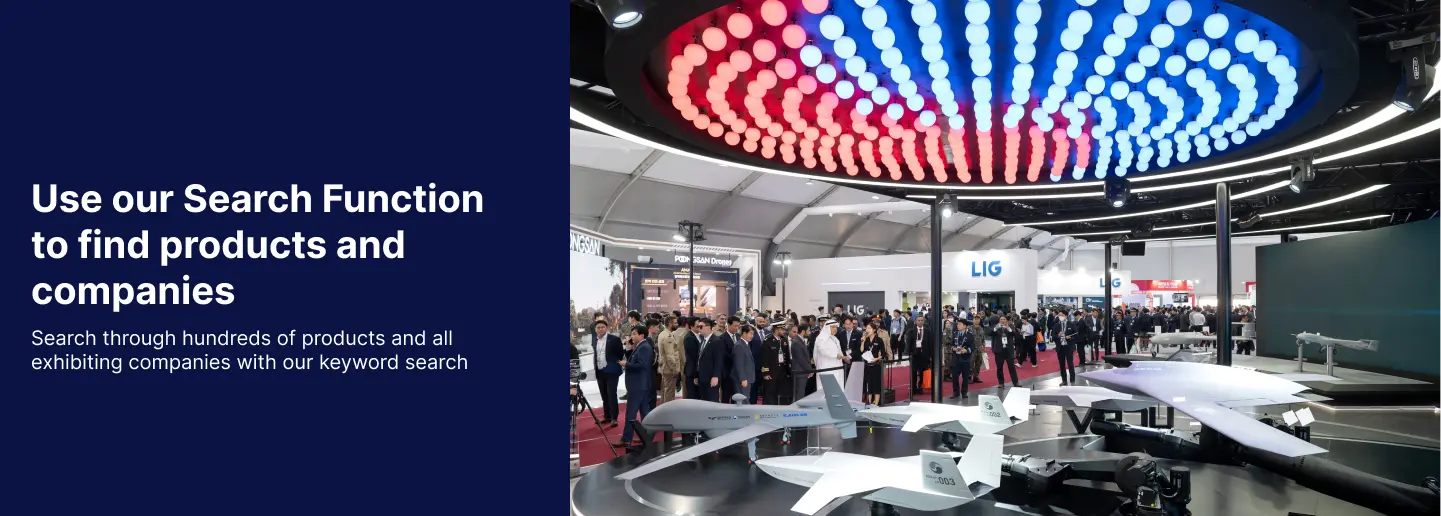

Advanced Search

Utilize our advanced search function to quickly locate products, people, and companies. Our state-of-the-art technology thoroughly scans all exhibitor information, delivering precise and relevant results

Interactive Floorplan

Navigate the show effortlessly with our directory. Use the floorplan to locate companies you want to visit and to find your way to onsite restaurants, toilets and site entrances and exits.

On-platform Messaging

Reach out to exhibitors and visitors directly on our platform to set up meetings, or request more information.

Some of our latest content

Companies, Products, News, Events

SU Optics

ACTUS® ARKS18 Precision Riflescope

The ACTUS® ARKS18 (1–8X28mm FFP) Riflescope is built to deliver precision and durability, meeting the demands of professional users across diverse environments.

Featuring a First Focal Plane (FFP) optical design, it ensures fast and accurate target coverage at any magnification level. The illuminated reticle provides smooth and reliable targeting, even in low-light conditions like dawn or dusk.

Whether in dynamic or harsh environments, the ACTUS® ARKS18 is the ultimate riflescope to meet the needs of users who require top-tier performance when it matters most.

EMCORE

TAC-450-360 Photonic Inertial Measurement Unit (IMU) (Non-ITAR)

Designed to deliver the highest level of performance, the non-ITAR TAC-450-360 IMU includes our exclusive photonic integrated chip (PIC) technology. The high-performance TAC-450-360 IMU is designed for applications in which high bandwidth, low latency, and low drift are critical. The TAC-450-360 IMU is integrated with inertial-grade accelerometers and three axes of magnetometers to provide the high accuracy levels that leading autonomous and manned platforms demand.

Highlights

Designed for ease of integration with flexible interface settings and programmable message outputs

Excellent performance in critical applications and the specs that matter most

Improved SWaP plus robust performance and survivability

Technology Details

Photonic Integrated Chip Technology

EMCORE’s photonic integrated chip (PIC) technology* reimagines FOG technology by replacing individual fiber components with an innovative integrated planar optic chip. This results in a FOG with PIC Inside™ that’s reliable and robust. With three of these integrated photonic gyros at its core, the TAC-450-360 IMU provides the safe, accurate performance autonomous platforms demand.

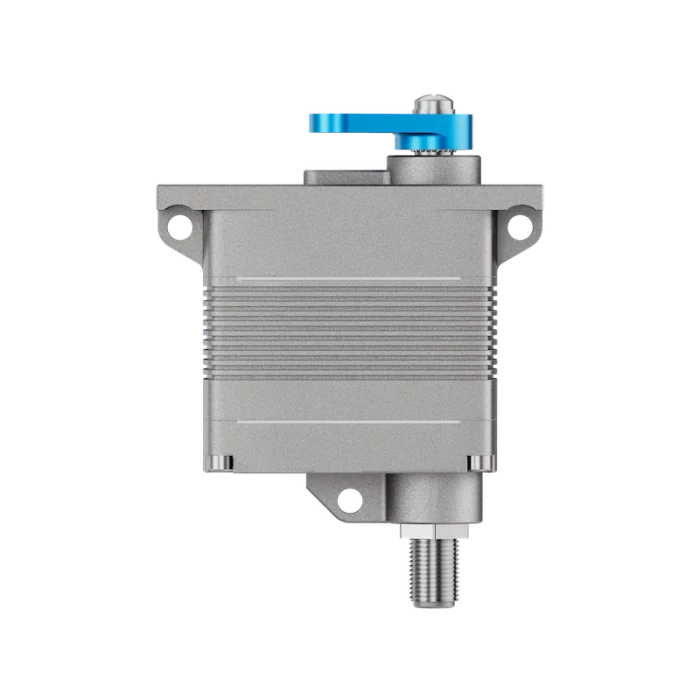

Volz Servos

DA 15-N

The DA 15‐N is our smallest and lightest full brushless actuator. Its brushless motor and contactless, wear-free position sensing system makes the DA 15‐N immune to wear, vibrations and shock loads. It has especially been designed for usage in harsh environments and for safety-critical applications that require an actuator with high endurance.

The conductive aluminum case and the shielded connection cable are reducing the susceptibility to any kind to EMI/RFI noise to the absolute minimum. The servo features position, temperature and current feedback as a standard and is fully programmable.

Haynes International

Aerospace

Since the company was founded, Haynes International has played a key role in the development of the aerospace industry. During World War I, Haynes STELLITE® alloy cutting tools proved to be vital in meeting the increased production of military aircraft engines.

View page in English

디렉터리 기능

전시회 도우미

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

방문 계획 수립

북마크 도구와 이벤트 플래너를 사용해 방문하고자 하는 기업과 관심 있는 제품을 검색하세요. 저장한 모든 항목을 조회할 수 있습니다

고급 검색

고급 검색 기능을 사용하여 상품, 인물, 기업의 위치를 빠르게 조회할 수 있습니다. 최첨단 기술을 통해 모든 참가사의 정보를 철저히 스캔하여 세밀하고 관련성 있는 정보를 제공합니다

상호작용 가능 평면도

디렉터리를 사용해 전시회를 손쉽게 둘러보세요. 방문하고자 하는 기업의 위치와, 행사장 내 식당, 화장실, 출입구를 평면도에서 찾을 수 있습니다.

플랫폼 내 메시지

플랫폼 상의 전시 참가사와 관람객에게 직접 연락하여 미팅을 신청하거나 추가 정보를 요청하세요.

최신 콘텐츠

기업, 상품, 뉴스, 이벤트

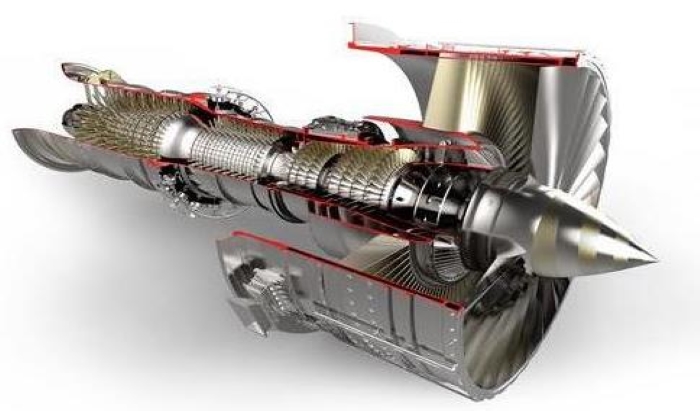

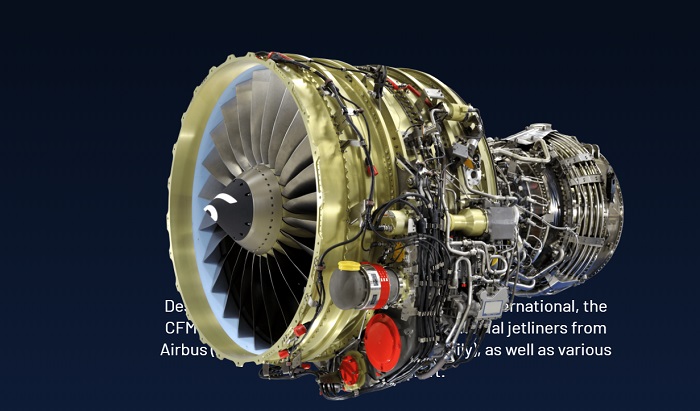

SAFRAN

CFM56 - The best-selling engine in commercial aviation history

With more than 33,000 delivered to date, CFM56® engines mainly power single-aisle commercial jets from Airbus and Boeing. The CFM56®, developing 18,500 to 33,000 lb of thrust, set a standard in this market. It owes its impressive success to exceptional performance and reliability, the result of the two partners' technical excellence.

Green Optics Co., Ltd.

Vis/SWIR Zoom Optics

1. Feature

- A common optical system supporting two wavelength bands (visible/SWIR) with a CAM structure, capable of up to 10× magnification.

BIBUS METALS KOREA

Chemical processing

NICKEL 200 / 201

Bars-Sheets and Plates-Tubes and Pipes

MONEL® ALLOY 400

Bars-Sheets and Plates-Tubes and Pipes

MONEL® ALLOY K-500

Bars

INCONEL® Alloy 600

Bars-Sheets and Plates-Tubes and Pipes-Wire

INCONEL® Alloy 601

Bars-Sheets and Plates-Tubes and Pipes-Wire

INCONEL® Alloy 625

Bars-Sheets and Plates-Tubes and Pipes

INCONEL® Alloy 625LCF®

Sheets and Plates

INCONEL® Alloy 693

Sheets and Plates-Tubes and Pipes

INCONEL® Alloy C-276

Bars-Sheets and Plates-Tubes and Pipes

INCONEL® Alloy 22

Bars-Sheets and Plates-Tubes and Pipes

INCOLOY® Alloy 800 H / HT

Bars-Sheets and Plates-Tubes and Pipes

INCOLOY® Alloy 825

Bars-Sheets and Plates-Tubes and Pipes

Titanium Grade 1

Strip

Titanium Grade 2

Bars-Sheets and Plates-Tubes and Pipes

Titanium Grade 7

Bars-Sheets and Plates-Tubes and Pipes

_700.webp)

DusiTech Co., Ltd.

KnX2 Drone

- Urban drones specialized in surveillance/spatial information/disaster safety/facility survey

- Completed localization of core components! Equipped with encryption KCMVP

Dimensions (WxLxH) : Flight / 360x360x160mm(h)

Folding / 260x260x160mm(h)

Airframe Weight : 2kg or less (max take-off weight)

GNSS : RTK / GNSS (SBAS supported)

Flight Time : 30 minutes

Digital Directory

Digital Directory