한국어로 페이지 보기

Seoul ADEX 2025 Digital Directory

Plan your trip to Seoul ADEX 2025 using our state of the art Digital Directory

Register in seconds with just your email

Directory Features

To help you at the show

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

Plan your trip

Use the bookmarking and event planning tool to research the companies you would like to visit and the products you are interested in finding. You will be able to locate all of your saved companies on our floorplan

Advanced Search

Utilize our advanced search function to quickly locate products, people, and companies. Our state-of-the-art technology thoroughly scans all exhibitor information, delivering precise and relevant results

Interactive Floorplan

Navigate the show effortlessly with our directory. Use the floorplan to locate companies you want to visit and to find your way to onsite restaurants, toilets and site entrances and exits.

On-platform Messaging

Reach out to exhibitors and visitors directly on our platform to set up meetings, or request more information.

Some of our latest content

Companies, Products, News, Events

_700.webp)

Kallman Worldwide, Inc.

Exhibitors Lounge

“The Meeting Point” is a private lounge where exhibitors can meet with guests, take a break from the show floor, and connect with industry peers. The Kallman Café serves refreshments throughout the day, offers a place to charge your phone, and provides exclusive WiFi service.

FINE KOWAC Co., Ltd.

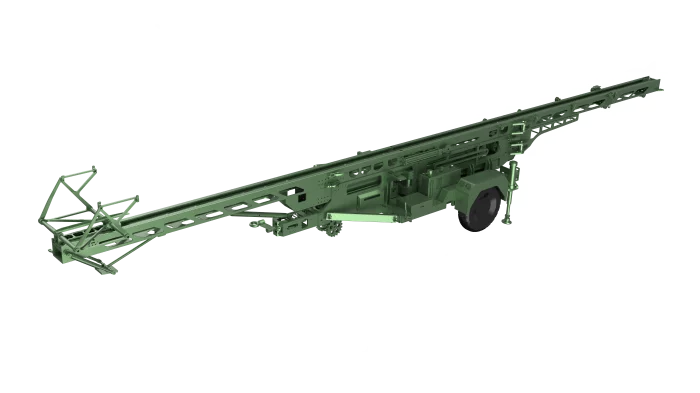

UAV Catapult Launcher

This is the UAV launchers capable of launching the fixed-wing UAVs even on mountainous terrain, field, ships without sufficient runways to take off. It is designed to be the most powerful and easy to operate to take off the fixed-wing type UAVs of various specifications(Take-off weight, Take-off speed, and allowable G-force) into the air.

It provides an interface that standardizes the shuttle for any type of unmanned aviation vehicle, and is easy to mount and to avoid take-off interference.

A specially designed and manufactured hydraulic actuator is used to fully cope with the take-off weight of the aircraft, and a proprietary accumulator to allow a wide range of launch speed control. And multiple pulleys are equipped to ensure acceleration performance.

JINYOUNG TBX CO.,LTD

Turbine Blades

Heat engine that converts combustion energy into mechanical energy.

It consists of a compressor, combustion chamber, and turbine, and is widely used in aircraft propulsion.

Sangdo Electronics co.,Ltd

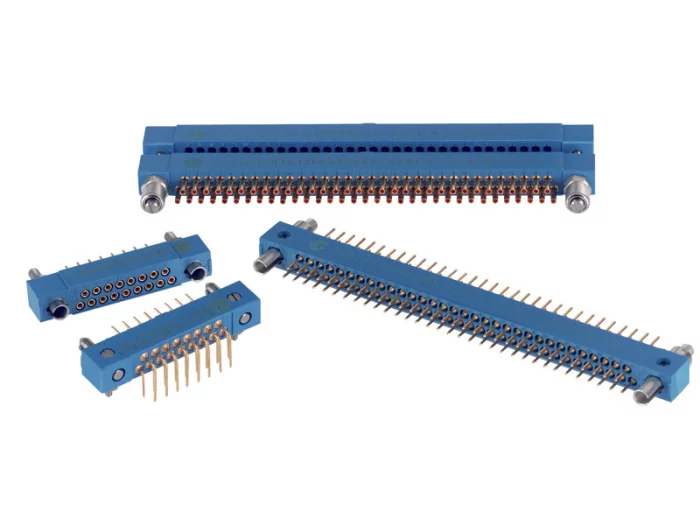

KNB/KNC Series

Based on the KN series MIL-DTL-55302 compliant connectors an ESA version of the KNB/KNC connectors has been created, which also offers signal contacts designed for demanding defense, commercial aerospace and space applications. They also are available in the 2 and 3 row series and offer flexibility not available with other interconnects.

View page in English

디렉터리 기능

전시회 도우미

In-depth Exhibitor Profiles

Each exhibitor can add as many products and services as they wish, with in-depth information and specifications. This allows buyers to find what they want easily.

Self Provisioning for Exhibitors

Each exhibitor has full control of their content - to edit their company profile, upload products and enter staff details.

방문 계획 수립

북마크 도구와 이벤트 플래너를 사용해 방문하고자 하는 기업과 관심 있는 제품을 검색하세요. 저장한 모든 항목을 조회할 수 있습니다

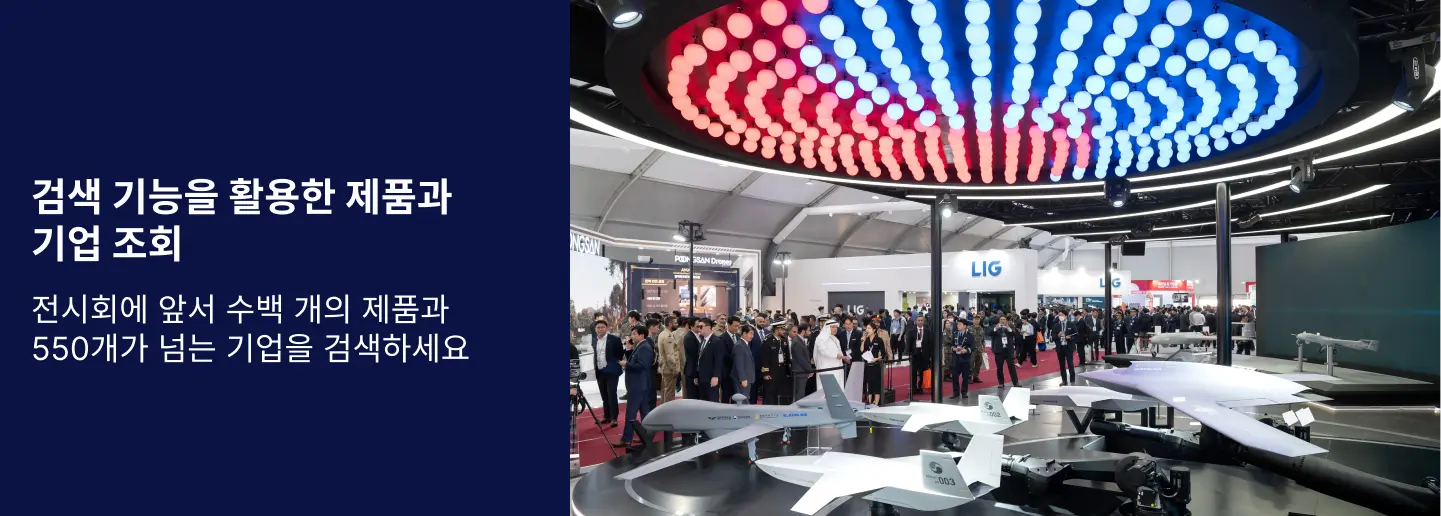

고급 검색

고급 검색 기능을 사용하여 상품, 인물, 기업의 위치를 빠르게 조회할 수 있습니다. 최첨단 기술을 통해 모든 참가사의 정보를 철저히 스캔하여 세밀하고 관련성 있는 정보를 제공합니다

상호작용 가능 평면도

디렉터리를 사용해 전시회를 손쉽게 둘러보세요. 방문하고자 하는 기업의 위치와, 행사장 내 식당, 화장실, 출입구를 평면도에서 찾을 수 있습니다.

플랫폼 내 메시지

플랫폼 상의 전시 참가사와 관람객에게 직접 연락하여 미팅을 신청하거나 추가 정보를 요청하세요.

최신 콘텐츠

기업, 상품, 뉴스, 이벤트

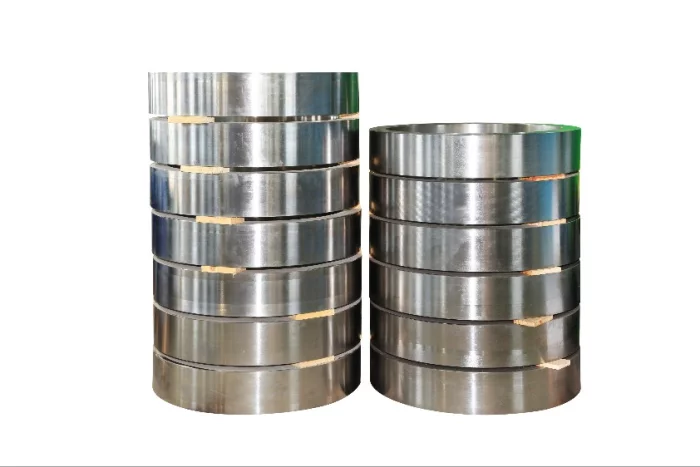

HANSCO

Aerospace Grade Aluminum Forgings

High-quality aerospace-grade aluminum forgings, produced from 6000 and 7000 series ingots sourced from reputable foundries. Our company specializes in forging and heat-treating to meet specific customer requirements, including ring and plate shapes, for defense industry applications.

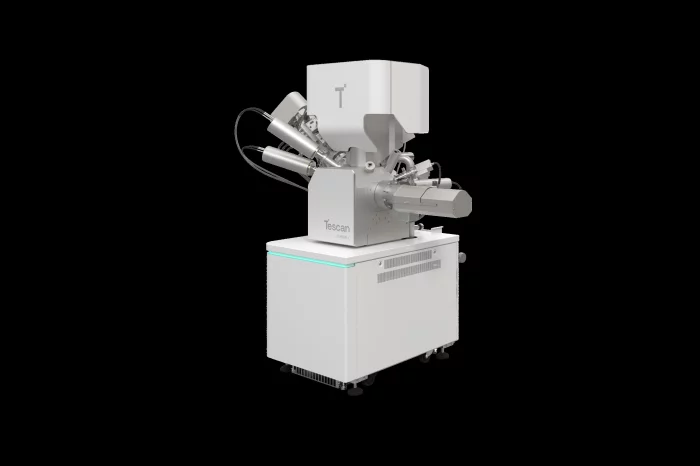

Tescan Group a.s.

TESCAN Plasma FIB-SEM, AMBER X2

An optimized Plasma FIB-SEM platform with proprietary gas chemistries for high-quality delayering of the most current semiconductor devices

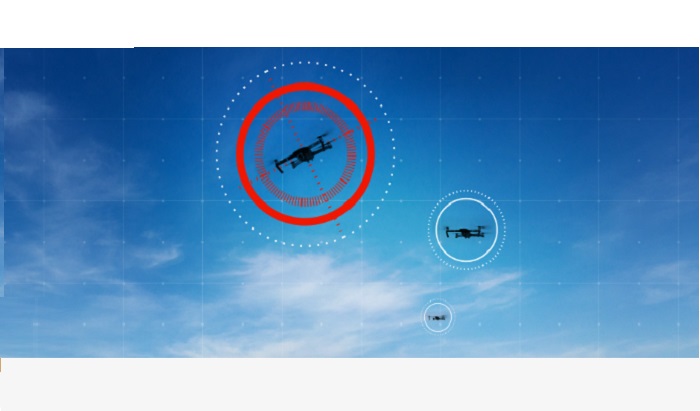

Teledyne FLIR LLC

Counter-UAS

Counter-UAS Solutions for Government & Defense

Integrated Procurement Technologies

CH-47

CH-47 CHINOOK

Digital Directory

Digital Directory