GE Aerospace Advances AI-Powered Blade Inspection Technology

Details

More Products & Services

Products & Services

Home - Aviation Group Marketing

Aviation Week Network

120 data points on over 156,000 commercial and business aviation aircraft, including military transports. Discover the most trustworthy resource for the complete aircraft history, plus ad hoc reports, month-over-month trend analysis and details on expected deliveries through 2050.

Aerospace | Aviation Week Network

Aviation Week Network

https://aviationweek.com/themes/custom/particle/dist/app-drupal/assets/awn-logo.svg

People

Andrea Rossi Prudente

Aviation Week Network

Becca Balmes

Aviation Week Network

Belinda Tan

Aviation Week Network

Brian Everstine

Aviation Week Network

Editor

Eddie Krankowski

Aviation Week Network

Assistant Manager, Tradeshows

erving dockery

Aviation Week Network

Lisa Tan

Aviation Week Network

Senior Marketing Manager

Mark Thomas

Aviation Week Network

Description

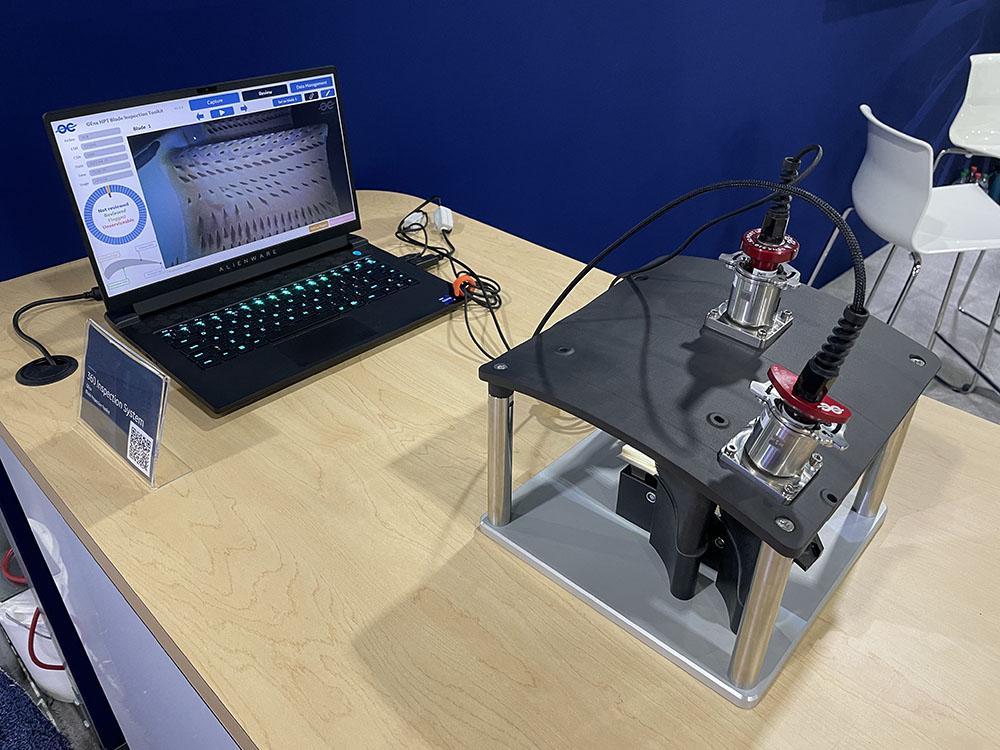

BARCELONA—GE Aerospace is expanding the use of its artificial intelligence-enabled blade inspection tool to its two most advanced commercial engine platforms.

GE, which first debuted the AI-enabled blade inspection tool (BIT) at MRO Americas last year, has been using the technology to improve speed, accuracy and consistency of GEnx engine inspections. The company is now releasing similar AI-enabled BITs for GE9X and CFM International Leap engine platforms.

According to GE, the use of AI for these types of inspections reduces turnaround times and maximizes time-on-wing for engines. It says BIT has cut blade inspection times in half and improved accuracy compared to standard borescope inspections.

“With the deployment of our AI-enabled BIT for the GEnx engine, we have seen inspection process times cut in half from 3-1.5 hr. while improving quality and accuracy,” says Nicole Jenkins, GE's chief MRO engineer. “What's particularly notable is that with the GE9X engine, we will have this advanced inspection tool ready when the engine enters service.”

BIT is just one of the various AI-powered MRO tools GE has recently developed. Last month, the company opened a new Services Technology Acceleration Center, where it is developing advanced engine inspection, repair and overhaul technologies that it intends to roll out across its global MRO network. One of the technologies it will focus on is GE's AI-guided white light robot inspections, which automate a previously manual process in which inspectors had to use a flashlight and mirror to visually interpret defects on high-precision parts, such as turbine disks. The AI component captures and analyzes inspection data while creating a digital record of the part's condition.

GE is also using AI-enabled fluorescent penetrant and borescope inspections through a partnership with Waygate Technologies. The companies have recently finished the first part of a joint technology development effort that has improved AI models to increase true positive findings and reduce false positive findings.

Waygate has added features to its AI-enhanced borescope tool to help inspectors find previously overlooked damage at the edges of borescope images, as well as a data anonymization tool to help its partners share data for AI development in a safe and trustworthy way. The technology will be deployed in GE's MRO environments later this year and will be available on Waygate's Mentor Visual iQ+ video borescope under the product name Gas Power-assist.

GE, which first debuted the AI-enabled blade inspection tool (BIT) at MRO Americas last year, has been using the technology to improve speed, accuracy and consistency of GEnx engine inspections. The company is now releasing similar AI-enabled BITs for GE9X and CFM International Leap engine platforms.

According to GE, the use of AI for these types of inspections reduces turnaround times and maximizes time-on-wing for engines. It says BIT has cut blade inspection times in half and improved accuracy compared to standard borescope inspections.

“With the deployment of our AI-enabled BIT for the GEnx engine, we have seen inspection process times cut in half from 3-1.5 hr. while improving quality and accuracy,” says Nicole Jenkins, GE's chief MRO engineer. “What's particularly notable is that with the GE9X engine, we will have this advanced inspection tool ready when the engine enters service.”

BIT is just one of the various AI-powered MRO tools GE has recently developed. Last month, the company opened a new Services Technology Acceleration Center, where it is developing advanced engine inspection, repair and overhaul technologies that it intends to roll out across its global MRO network. One of the technologies it will focus on is GE's AI-guided white light robot inspections, which automate a previously manual process in which inspectors had to use a flashlight and mirror to visually interpret defects on high-precision parts, such as turbine disks. The AI component captures and analyzes inspection data while creating a digital record of the part's condition.

GE is also using AI-enabled fluorescent penetrant and borescope inspections through a partnership with Waygate Technologies. The companies have recently finished the first part of a joint technology development effort that has improved AI models to increase true positive findings and reduce false positive findings.

Waygate has added features to its AI-enhanced borescope tool to help inspectors find previously overlooked damage at the edges of borescope images, as well as a data anonymization tool to help its partners share data for AI development in a safe and trustworthy way. The technology will be deployed in GE's MRO environments later this year and will be available on Waygate's Mentor Visual iQ+ video borescope under the product name Gas Power-assist.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link

Digital Directory

Digital Directory