GE Aerospace Develops AI Maintenance Records Tool

Details

More Products & Services

Products & Services

Home - Aviation Group Marketing

Aviation Week Network

120 data points on over 156,000 commercial and business aviation aircraft, including military transports. Discover the most trustworthy resource for the complete aircraft history, plus ad hoc reports, month-over-month trend analysis and details on expected deliveries through 2050.

Aerospace | Aviation Week Network

Aviation Week Network

https://aviationweek.com/themes/custom/particle/dist/app-drupal/assets/awn-logo.svg

People

Andrea Rossi Prudente

Aviation Week Network

Becca Balmes

Aviation Week Network

Belinda Tan

Aviation Week Network

Brian Everstine

Aviation Week Network

Editor

Eddie Krankowski

Aviation Week Network

Assistant Manager, Tradeshows

erving dockery

Aviation Week Network

Lisa Tan

Aviation Week Network

Senior Marketing Manager

Mark Thomas

Aviation Week Network

Description

GE Aerospace has developed a new tool that uses generative artificial intelligence to allow airlines and lessors to access critical maintenance records of assets faster. The company is hoping the technology could reduce hours of work searching maintenance records into minutes.

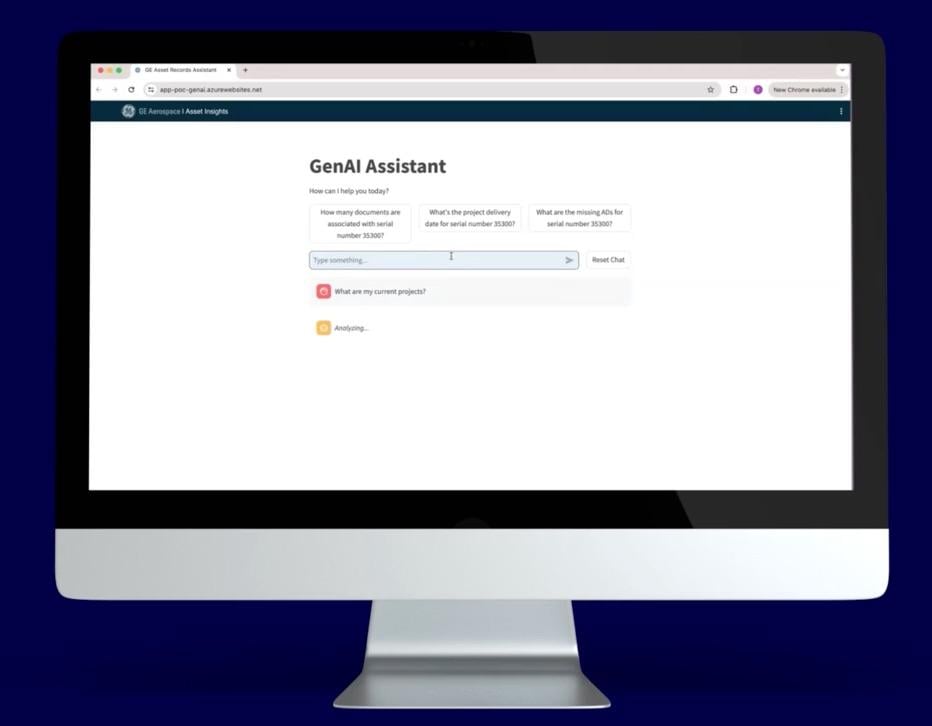

Developed in partnership with Microsoft and Accenture, the proof of concept—currently called GenAI Assistant—can be used to inform customers about leasing details, gaps in documents and technical status of leased aircraft. According to GE Aerospace, this critical information helps airlines and lessors protect asset value and proactively identify contractual compliance concerns, but it has traditionally involved a time-intensive manual collection process since it requires combing through multiple physical documents and data sets.

“We are told the current process of compiling asset and project data for transition status reporting can take up to a full day,” says a representative for GE Aerospace. “Our aim is to simplify that down to minutes by enabling advanced queries and generative AI to compile necessary asset and documentation data from multiple sources.”

Over the summer, lessor Carlyle Aviation Partners tested GenAI Assistant in a private preview, with initial results showing that the tool could save what GE says is multiple hours of work. “This has the potential to open so many opportunities to actively manage our fleet, giving us instant access to data and information that would normally take hours, days or even weeks to find,” says Donal Mc Gowan, Carlyle's senior vice president of technical management.

According to a representative for GE Aerospace, one example of how the tool could be used is for users to ask it about a specific airworthiness directive. “Our solution will tell them a summary of the requirement, corresponding work orders, completion status or the repeat inspection interval,” he says. “We see this capability as enabling a fundamentally different way of interacting with technical records and data, enabling customers to identify and interact with documentation without manual document indexing processes.”

GE, Accenture and Microsoft are working to add mobile capability to GenAI Assistant and to enable Azure AI and chat functionality within the production environment. The companies are targeting readiness in 2025.

GE Aerospace has developed a variety of other AI innovations across its businesses, many of which have specific MRO use cases. The company has developed AI-powered blade inspection tools for GEnx, GE9X and CFM International Leap engines, and it is working with Waygate Technologies to provide AI-assisted borescope inspections.

It is also using AI to monitor engine performance for predictive maintenance, to track fuel usage and optimize fuel efficiency, and to forecast engine work scopes and parts required for repairs prior to engine induction.

Developed in partnership with Microsoft and Accenture, the proof of concept—currently called GenAI Assistant—can be used to inform customers about leasing details, gaps in documents and technical status of leased aircraft. According to GE Aerospace, this critical information helps airlines and lessors protect asset value and proactively identify contractual compliance concerns, but it has traditionally involved a time-intensive manual collection process since it requires combing through multiple physical documents and data sets.

“We are told the current process of compiling asset and project data for transition status reporting can take up to a full day,” says a representative for GE Aerospace. “Our aim is to simplify that down to minutes by enabling advanced queries and generative AI to compile necessary asset and documentation data from multiple sources.”

Over the summer, lessor Carlyle Aviation Partners tested GenAI Assistant in a private preview, with initial results showing that the tool could save what GE says is multiple hours of work. “This has the potential to open so many opportunities to actively manage our fleet, giving us instant access to data and information that would normally take hours, days or even weeks to find,” says Donal Mc Gowan, Carlyle's senior vice president of technical management.

According to a representative for GE Aerospace, one example of how the tool could be used is for users to ask it about a specific airworthiness directive. “Our solution will tell them a summary of the requirement, corresponding work orders, completion status or the repeat inspection interval,” he says. “We see this capability as enabling a fundamentally different way of interacting with technical records and data, enabling customers to identify and interact with documentation without manual document indexing processes.”

GE, Accenture and Microsoft are working to add mobile capability to GenAI Assistant and to enable Azure AI and chat functionality within the production environment. The companies are targeting readiness in 2025.

GE Aerospace has developed a variety of other AI innovations across its businesses, many of which have specific MRO use cases. The company has developed AI-powered blade inspection tools for GEnx, GE9X and CFM International Leap engines, and it is working with Waygate Technologies to provide AI-assisted borescope inspections.

It is also using AI to monitor engine performance for predictive maintenance, to track fuel usage and optimize fuel efficiency, and to forecast engine work scopes and parts required for repairs prior to engine induction.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link

Digital Directory

Digital Directory